Please refresh page if loading fails

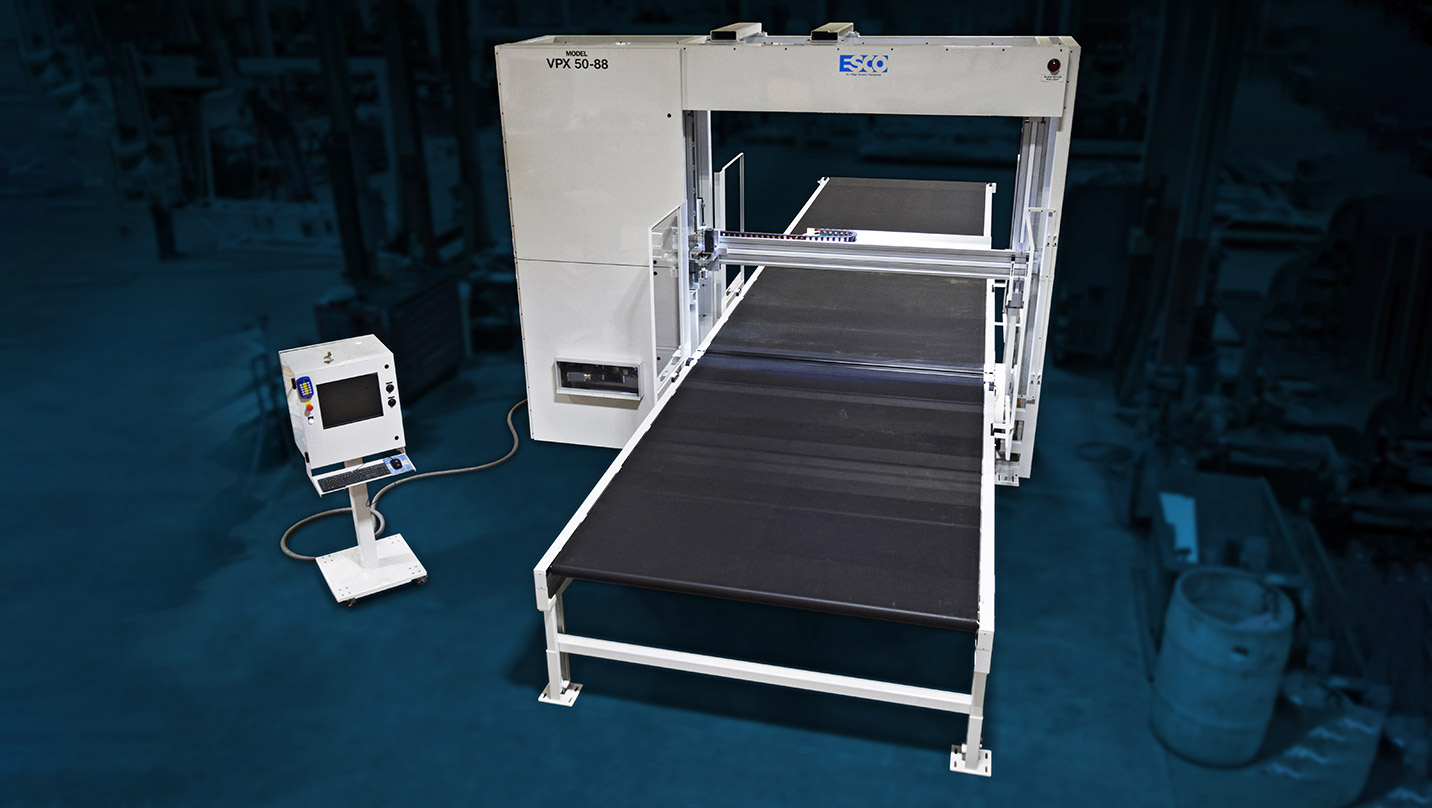

The VPX [U.S. Patent No. 10,882,126] CNC blade contour saw is a fast and compact vertical CNC foam saw for processing blocks or stacks of sheets of foam or non-woven products.

The VPX top speed of 75m/min (240ft/min) allows for very high output for the most demanding foam fabrication applications.

Overview

The VPX [U.S. Patent No. 10,882,126] vertical profile saw is a fast and efficient machine for cutting flexible polyurethane foams and non-woven fiber products. Offering a compact patented machine design and efficient use of key drive components the VPX is a cost effective and advanced vertical foam contour bandsaw for high volume foam fabrication applications.

ESCO's VPX is the perfect choice for high volume fabrication of foam cushions for furniture production. The VPX vertical CNC foam saw can process stacks of foam up to 1.3m (50") tall. Both reticulated foams and densified non-woven fiber products used in marine and outdoor furniture applications process very well on the VPX. The VPX may also be used for block trimming applications as well as for high speed mattress trimming.

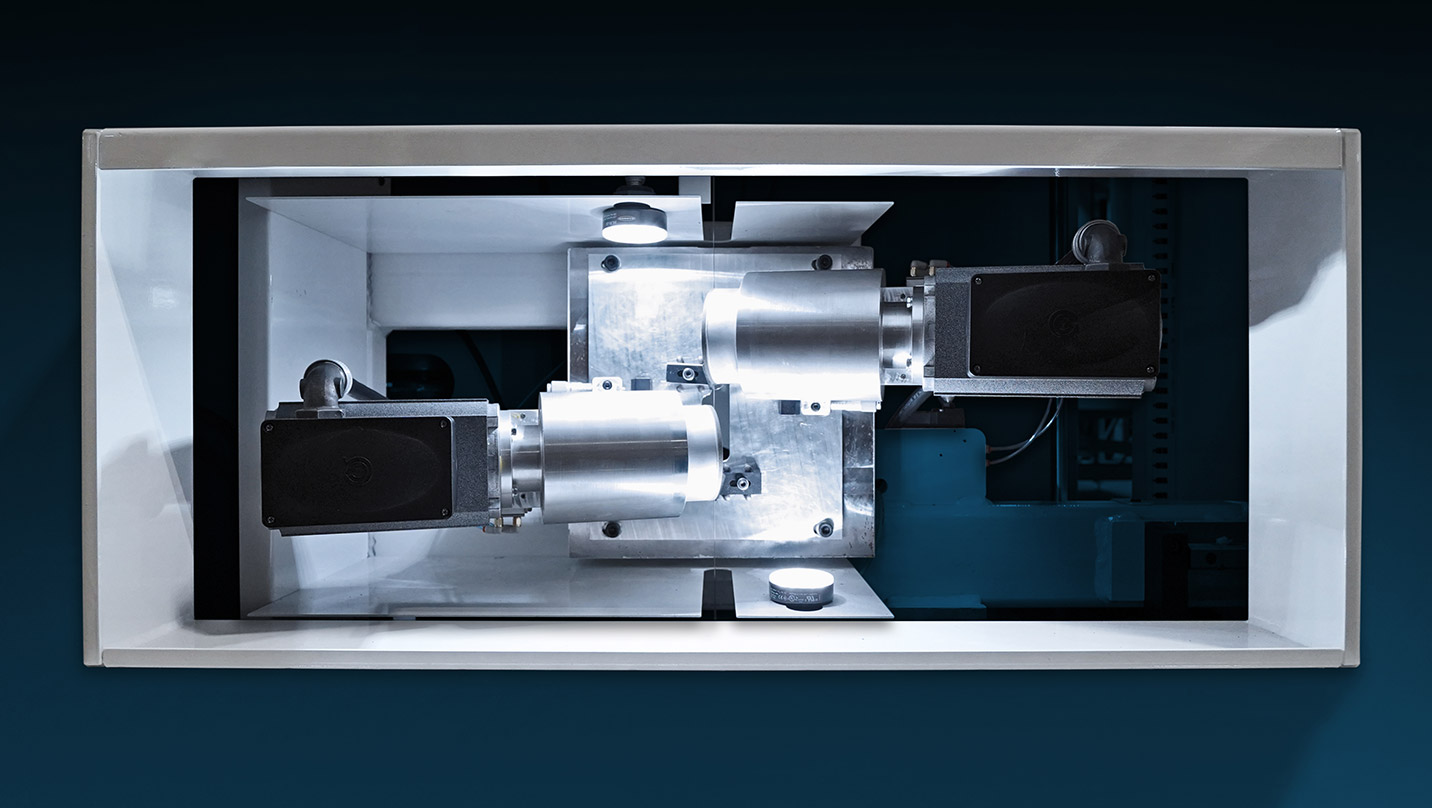

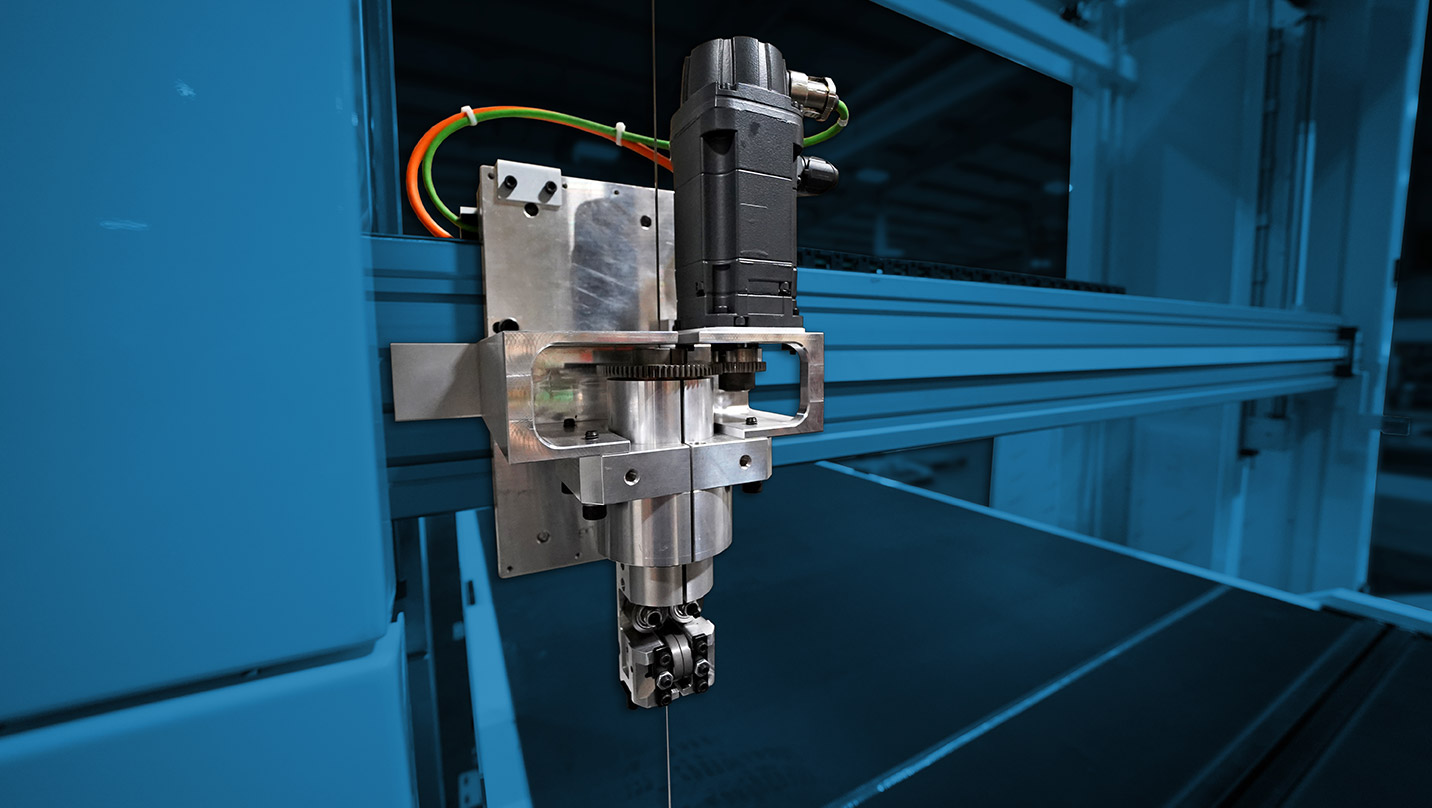

Utilizing a 3.5mm band knife the VPX can turn the blade up to 370 degrees which allows for complete processing of a part profile without the need for untwisting the blade. The VPX can run a wide range of blade profiles from toothed blades to double beveled band knife. If the end use is for cutting non-woven fibers products then the machine must be configured with a blade sharpening system. ESCO's precision sharpening system creates and maintains a razor edge and is programable to allow for automated sharpening cycles.

The VPX vertical profile saw can be setup as a standalone machine or configured to function in an automated foam cutting line. The VPX CNC bandsaw may also be configured with synchronized infeed conveyors for processing long blocks or long sheets/rolls of non-woven fiber. Scissor lifts conveyors for loading sheet or blocks of material on the machine.

Coupled with ESCO's advanced nesting software and cut path generator operators can quickly create high yield nested layouts with very little effort. Making straight cuts and rectangles is quick and easy with ESCO custom software as well.

In 2017 the VPX 36-60 was introduced for fabricators looking for a vertical CNC blade contour saw, but did not require a full-size cutting platform

Common Applications

Furniture, upholstery, packaging, medical, sleep / mattress, marine

Commonly Processed Materials

Flexible polyurethanes, high resilience foams [HR foam], non-woven fibers, cellulose foams, flexible foam, crosslinked PU

Download Brochure

VPX Specifications [Downloadable PDF][Opens in New Window]

Descargar folleto

VPX Especificaciones [Descargable PDF][Se abre en ventana nueva]

Overview

Operator Controls

Blade Assembly

Power Requirements

| Specifications | ||

|---|---|---|

| Models | VPX 50-88 | VPX 36-60 |

| Blade Speed | Variable | Variable |

| Cutting Speed | 240 FT/MIN [75 M/MIN] | 240 FT/MIN [75 M/MIN] |

| Cutting Width | 88 IN [2235 MM] | 60 IN [1524 MM] |

| Cutting Height | 50 IN [1270 MM] | 36 IN [914 MM] | Cutting Length | 120 IN [3048 MM] | 120 IN [3048 MM] |

| Floor Space Required | ||

| Overall Width | 172 IN [4368 MM] | 143 IN [3632 MM] |

| Overall Length | 267 IN [6781 MM] | 219 IN [5562 MM] |

| Maximum Height | 138 IN [3505 MM] | 109 IN [2768 MM] |

| Safety Zone [Recommended] - 36 IN [0.9 M] Around Entire Machine | ||

Subscribe to our newsletter to keep up with the latest news + events