Please refresh page if loading fails

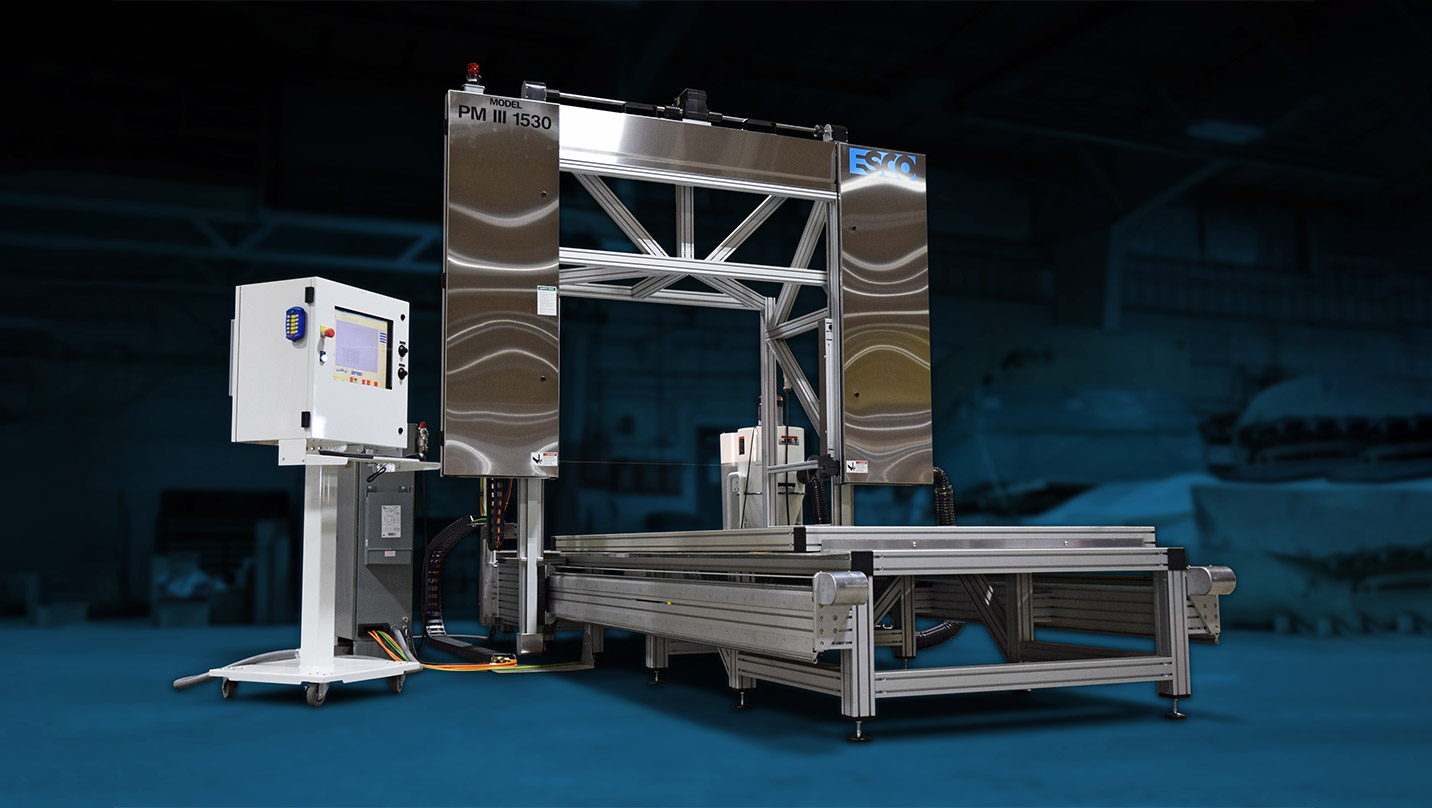

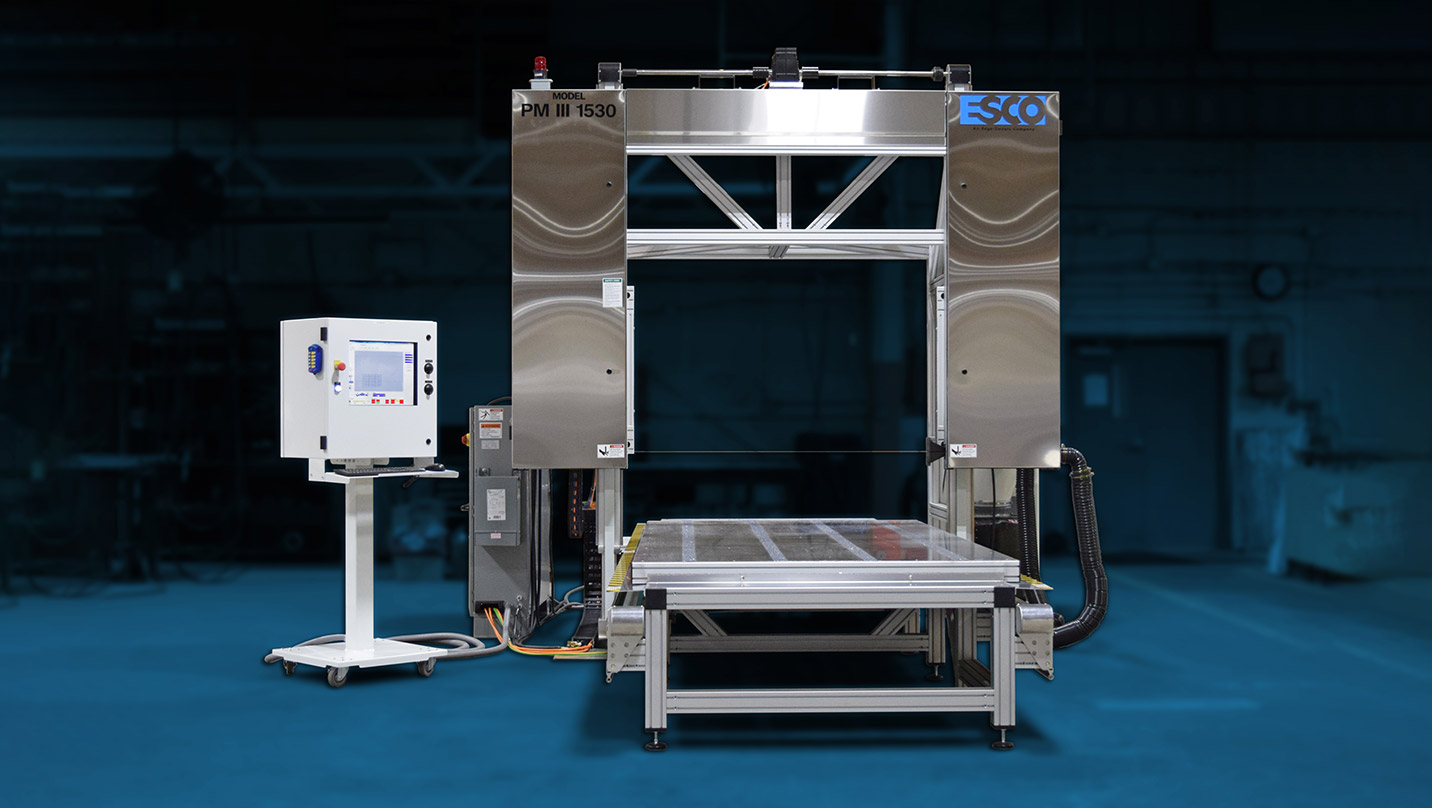

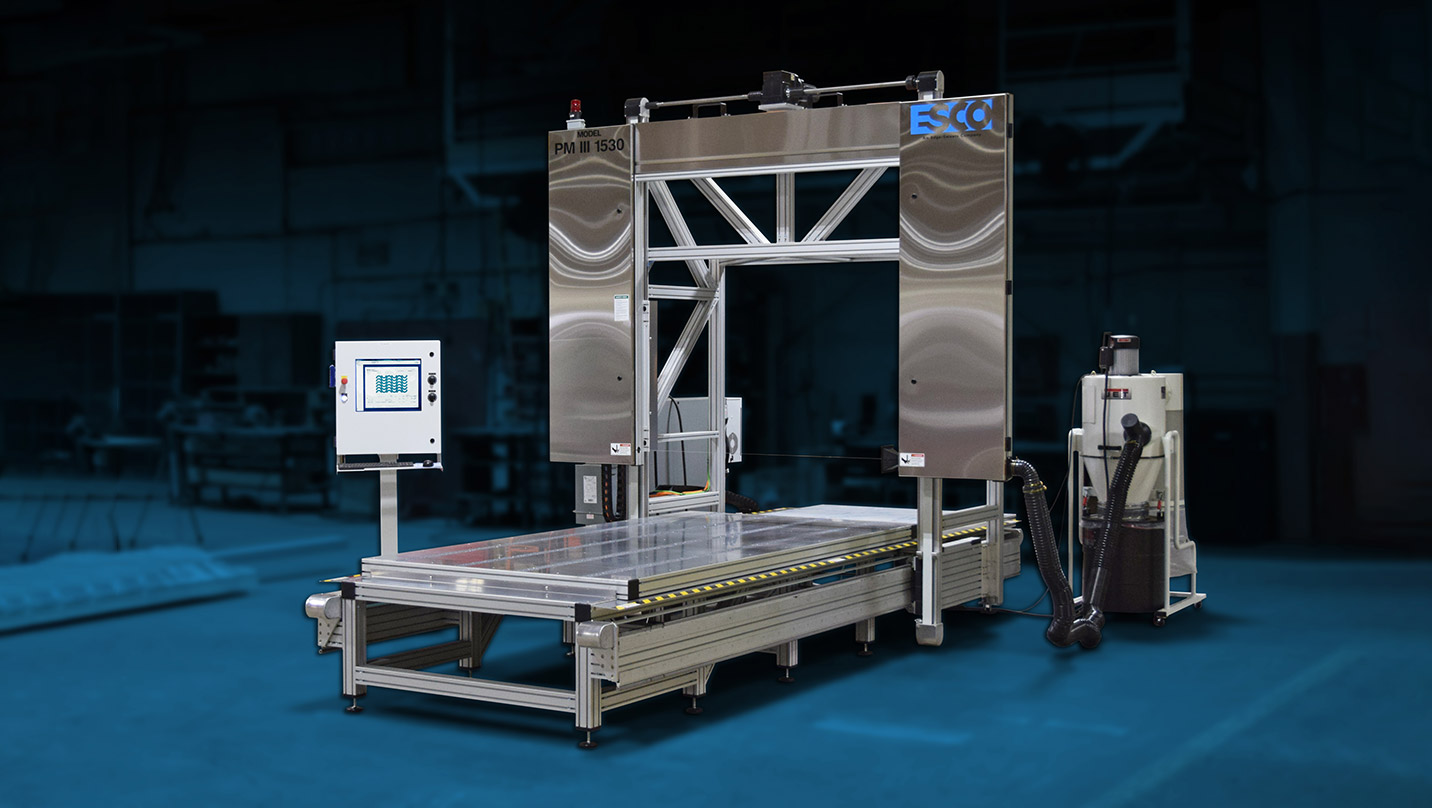

ESCO’s ProfileMatic III CNC profile cutting wire saw is the third generation of ESCO's highly popular and successful line of abrasive wire contour cutting machines. Dominating the wire contour saw market in North America the PM III has become the insulation fabricators work horse by coupling the machine, user and materials together with ESCO’s uniquely specialized software for automatic pipe insulation production.

Overview

NOTE : The video shown above has a playlist menu of similar PMIII videos in the top-left corner [Click menu to view]

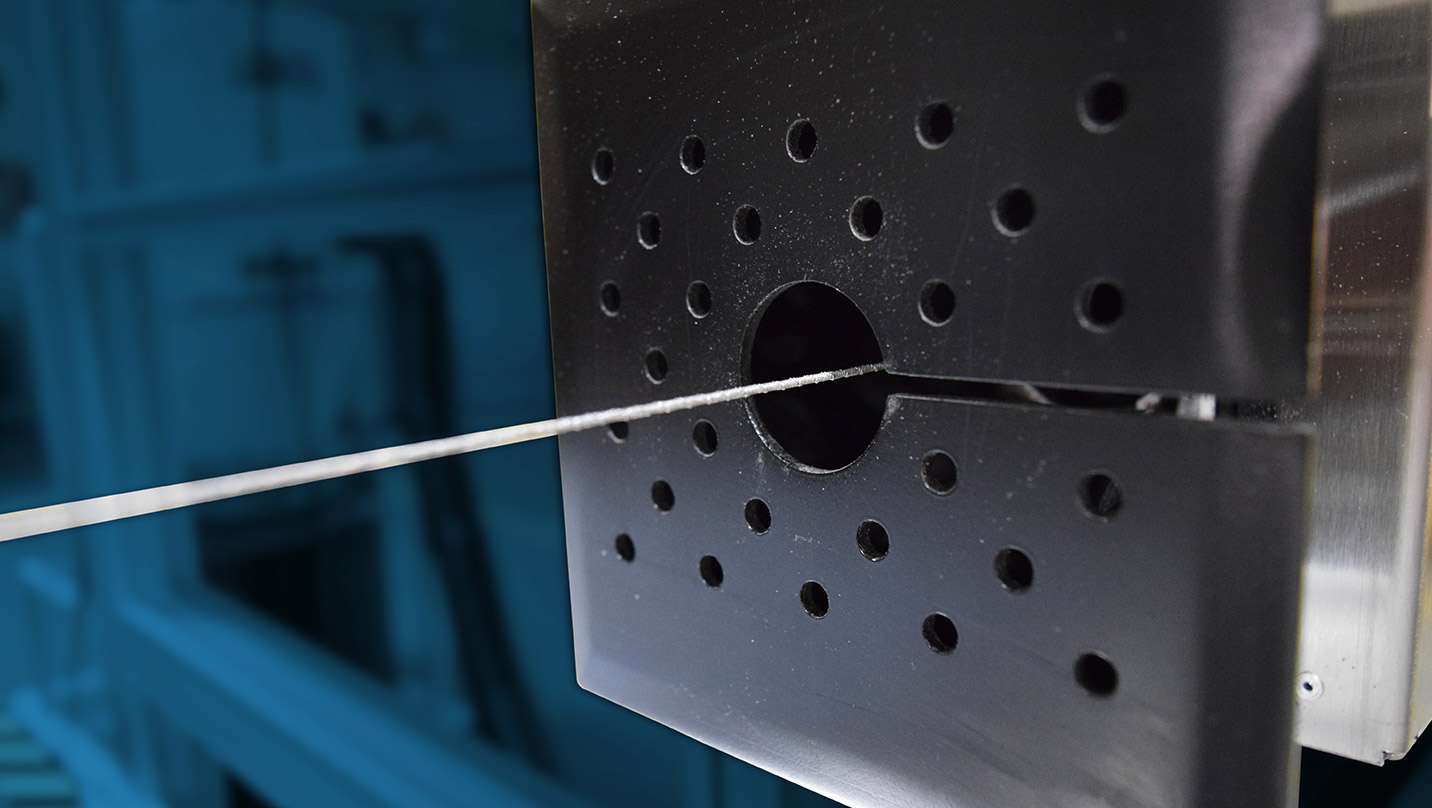

ESCO's ProfileMatic III CNC profile saw is the third generation of ESCO's highly popular and successful line of abrasive wire contour cutting machines. Utilizing precision gearboxes, motion controls, servos and drives, ESCO's Profilematic III or (PM III for short) is able to process both rigid and flexible polyurethanes with efficiency, accuracy and precision.

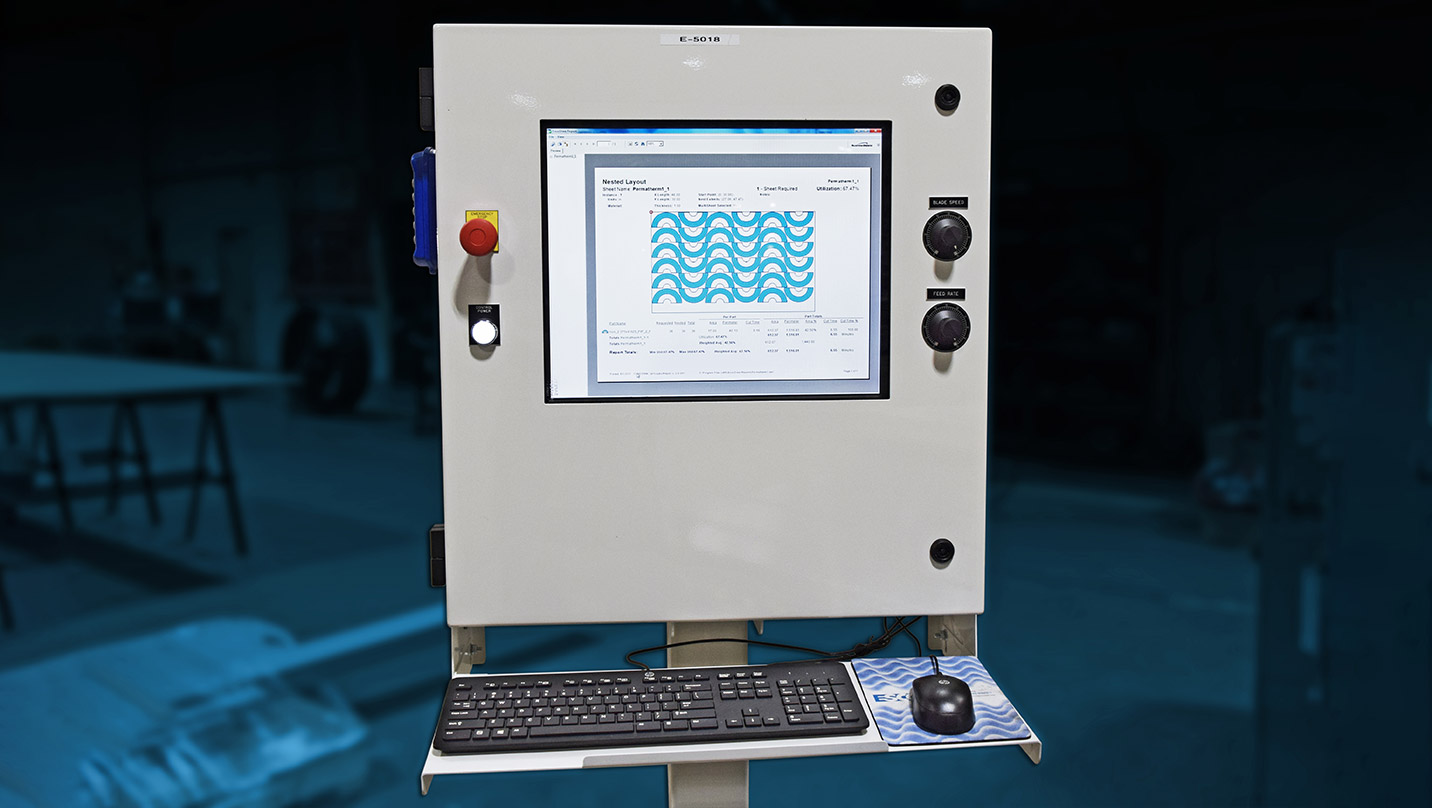

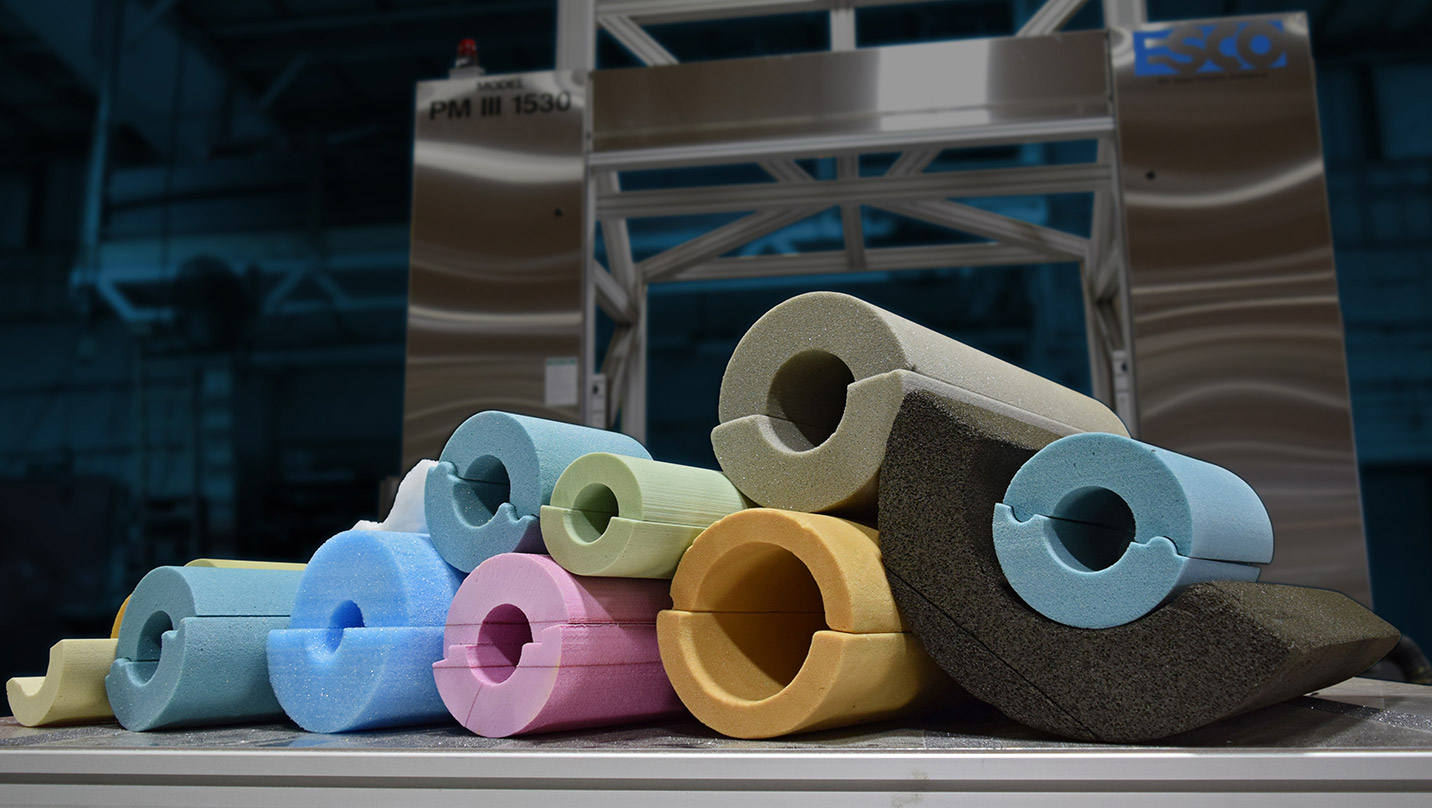

ESCO’s PM III horizontal wire profile saw is the most widely adopted machine in the USA for processing industrial insulation. Coupled with ESCODraw Pro nesting and layout management software, the ProfileMatic III is extremely user-friendly and easy to operate. Additionally, ESCODraw Pro has highly specialized pipe insulation (pipe cover) generation and nesting capabilities. To generate pipe insulation the operator simply inputs the size of the block of material, selects the desired pipe insulation size(s) from the American Society for Testing and Materials (ASTM) chart for either iron or copper pipe, then specifies the appropriate quantities for each pipe cover specified, nests the data and runs the resulting nested file on the CNC machine. With the ASTM chart preloaded into ESCODraw, it is not necessary to draw each pipe size and store the files for use. ESCODraw Pro creates the files on the fly, thus simplifying and streamlining the pipe insulation manufacturing process.

The highly specialized pipe generation and nesting features in ESCODraw Pro, in addition to the preconfigured ASTM chart, include: six pipe cover joint types; flush, overlapping (lap joint), semicircular, triangular, dovetail and custom joints; common line pipe insulation cutting (pipe in pipe), with infinite number of layers; seven unique clustering options utilized during nesting for efficient layout generation, grid fitting options to align parts in a uniform grid layout to maximize cutting efficiency, configurable part fitting options to allow the nesting software to fit parts from 1-360 degree fitting iterations; and a highly specialized cut path generation algorithm that compensates for wire diameter and part shifting/falling during cutting of rigid insulation materials.

Common Applications

Insulation, furniture, upholstery, packaging, medical, sleep / mattress, marine, automotive, acoustic + radio frequency [RF] management

Commonly Processed Materials

Polyisocyanurate [PIR], trymer, rigid PU, FoamGlas® [Cellular Glass], mineral wool / mineral fiber, calcium silicate, expanded polystyrene [EPS], crosslinked polyethylene [XLPE], polyethylene, expanded polypropylene [EPP], phenolic foams, rebond foam, reticulated foam, flexible polyurethanes, high resilience foams [HR Foams], non-woven fibers, flexible foam, crosslinked PU, IMPAXX

Cutting FoamGlas®

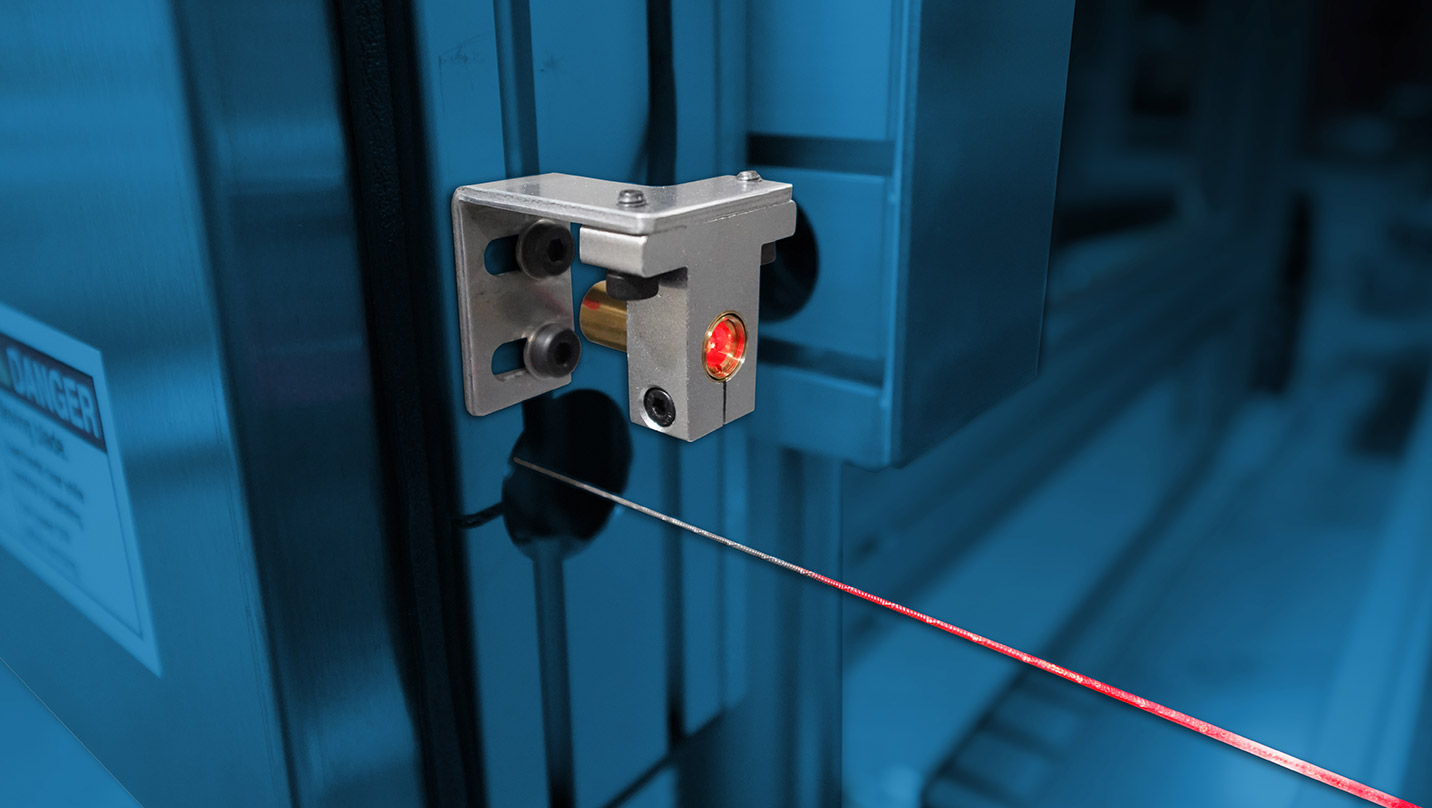

Another exciting feature of the ProfileMatic III horizontal wire saw is the ability to effectively cut Pittsburg Corning's FoamGlas®(cellular glass). The first challenge of cutting highly abrasive materials such as FoamGlas®, mineral fiber and calcium silicate is to use a tungsten cutting wire which ESCO has perfected with its suppliers. ESCO proprietary tungsten cutting wire can withstand the aggressive nature of highly abrasive materials.

Additionally, ESCO has perfected a system allowing fabricators to assemble large blocks of FoamGlas® and other insulation materials that are only produced in small blocks. From these smaller block of FoamGlas® fabricators can use products such as StrataFab® or Hydrocal® (gypsum cement) to produce large aggregated blocks. The ProfileMatic is able to detect the grout lines and slow down the machine to user defined speeds so as to allow the cutting wire sufficient time to process the very thick and difficult to cut grout lines.

Download Brochure

PMIII Specifications [Downloadable PDF][Opens in New Window]

Descargar folleto

PMIII Especificaciones [Descargable PDF][Se abre en ventana nueva]

Operator Controls

Power Requirements

PMIII Model Cutting Specifications

Models

Cutting Width

Cutting Length

1530

1500 MM [1.5 M or 4.9 FT]

3000 MM [3 M or 9.8 FT]

1550

1500 MM [1.5 M or 4.9 FT]

5000 MM [5 M or 16.4 FT]

1570

1500 MM [1.5 M or 4.9 FT]

7000 MM [7 M or 23 FT]

15100

1500 MM [1.5 M or 4.9 FT]

10000 MM [10 M or 32.8 FT]

2030

2000 MM [2 M or 6.5 FT]

3000 MM [3 M or 9.8 FT]

2525

2500 MM [2.5 M or 8.2 FT]

2500 MM [2.5 M or 8.2 FT]

2550

2500 MM [2.5 M or 8.2 FT]

5000 MM [5 M or 16.4 FT]

3030

3000 MM [3 M or 9.8 FT]

3000 MM [3 M or 9.8 FT]

3050

3000 MM [3 M or 9.8 FT]

5000 MM [5 M or 16.4 FT]

Cutting Height [All Models] 1270 MM [50 IN, 1.3 M, 4.2 FT]

| Specifications [Information based on Model 1530] | |

|---|---|

| Technology | CNC operated machine with HMI computer including ESCOView and ESCODraw software |

| Wire Speed | Variable |

| Cutting Speed | 400 IN/MIN [10 M/MIN] |

| System Pressure | 70 PSI continuous pressure |

| Max Cutting Dimensions | |

| Cutting Width | 1.5 M [4.9 FT or 59 IN] or 2.5 M [8.2 FT or 98 IN] |

| Cutting Length | 3 M [9.8 FT or 118 IN] with optional 5 M [16.4 FT or 197 IN], then in increments of 1 M [3.3 FT or 39 IN] up to 10 M [32.8 FT or 393 IN] |

| Cutting Height | 1270 MM [50 IN, 1.3 M, 4.2 FT] |

| Floor Space Required | |

| Overall Machine Width | 3 M [9.8 FT or 118 IN] or 3.6 M [11.8 FT or 141 IN] with electrical enclosure |

| Overall Machine Length | 5.8 M [19 FT or 228 IN] |

| Maximum Machine Height | 4 M [13.1 FT or 157 IN] |

| Safety Zone [Recommended] | 0.9 M [3 FT or 36 IN] around entire machine |

| Shipping weight is approximately 1588 KG [3500 LBS] | |

Subscribe to our newsletter to keep up with the latest news + events