Please refresh page if loading fails

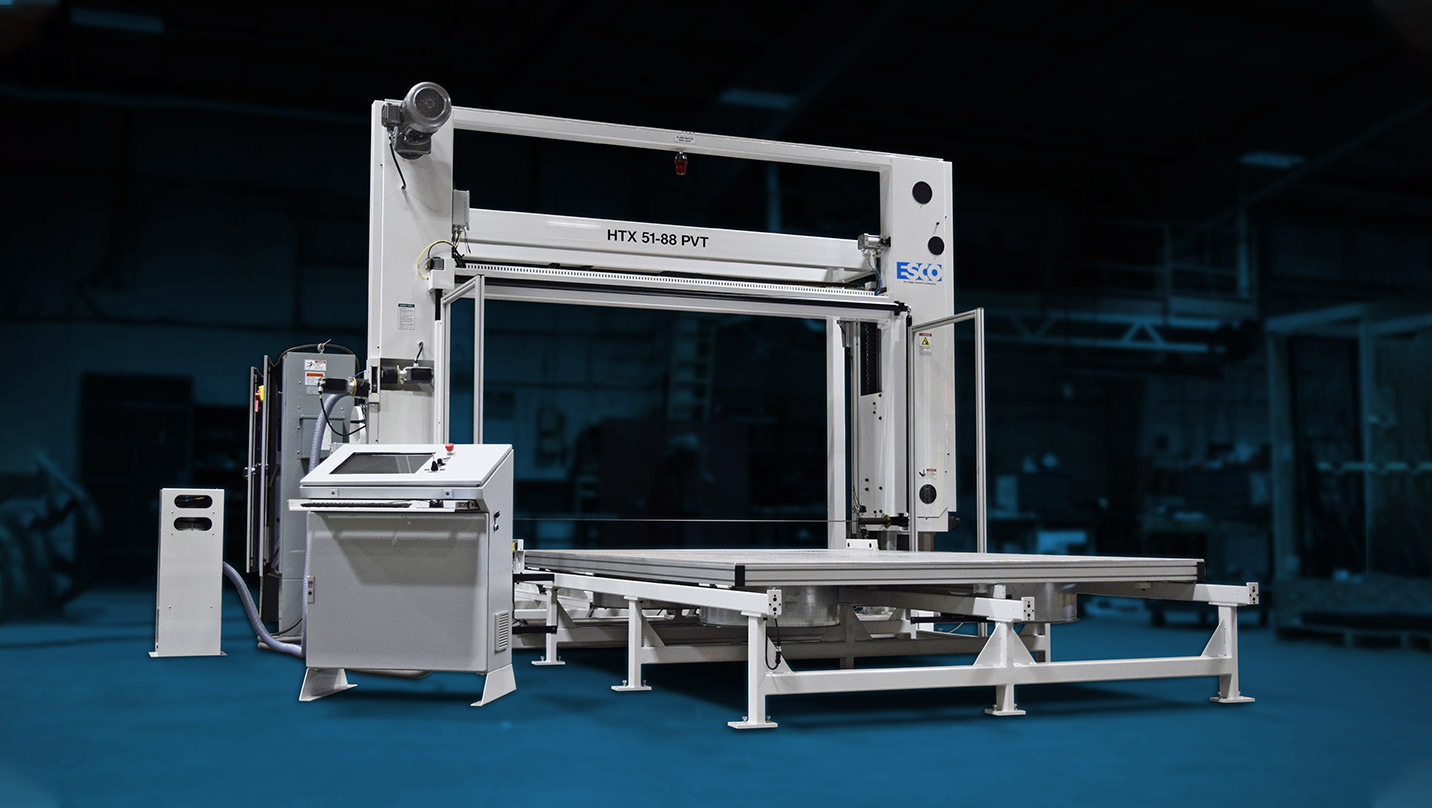

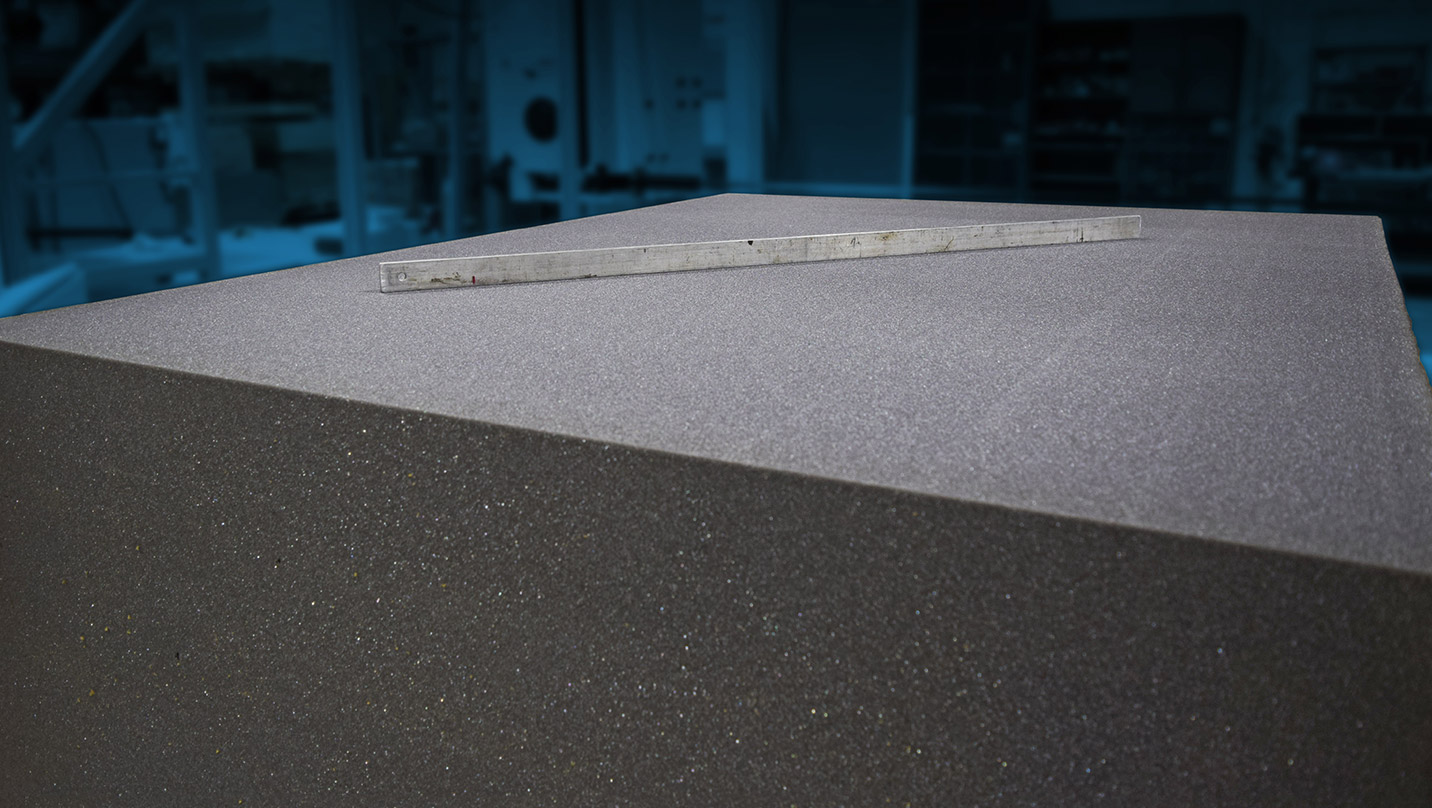

The HTX line of foam slitters are high-speed, high-tension and high-precision slitting machines capable of accurately converting a wide range of polyurethane foam blocks into sheets.

Overview

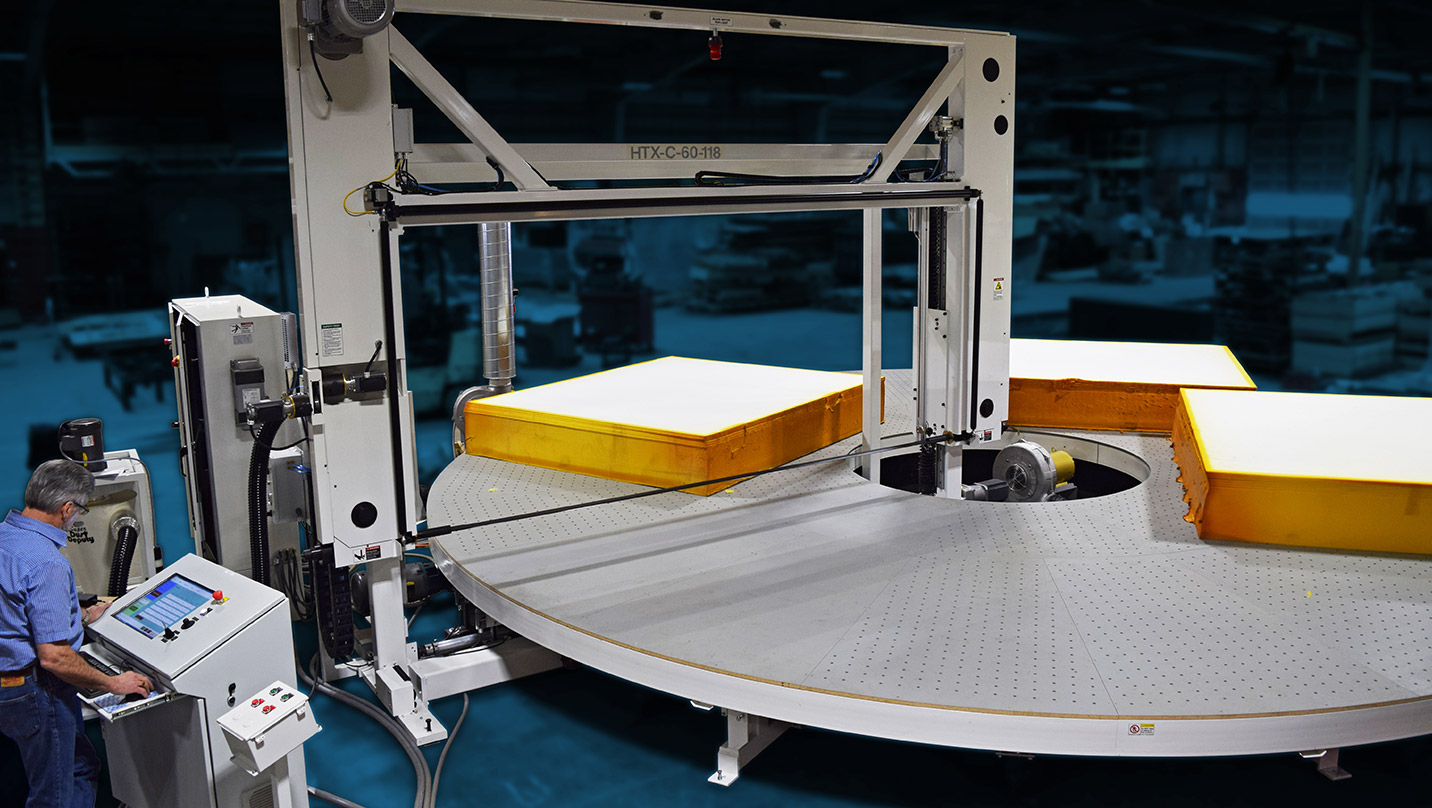

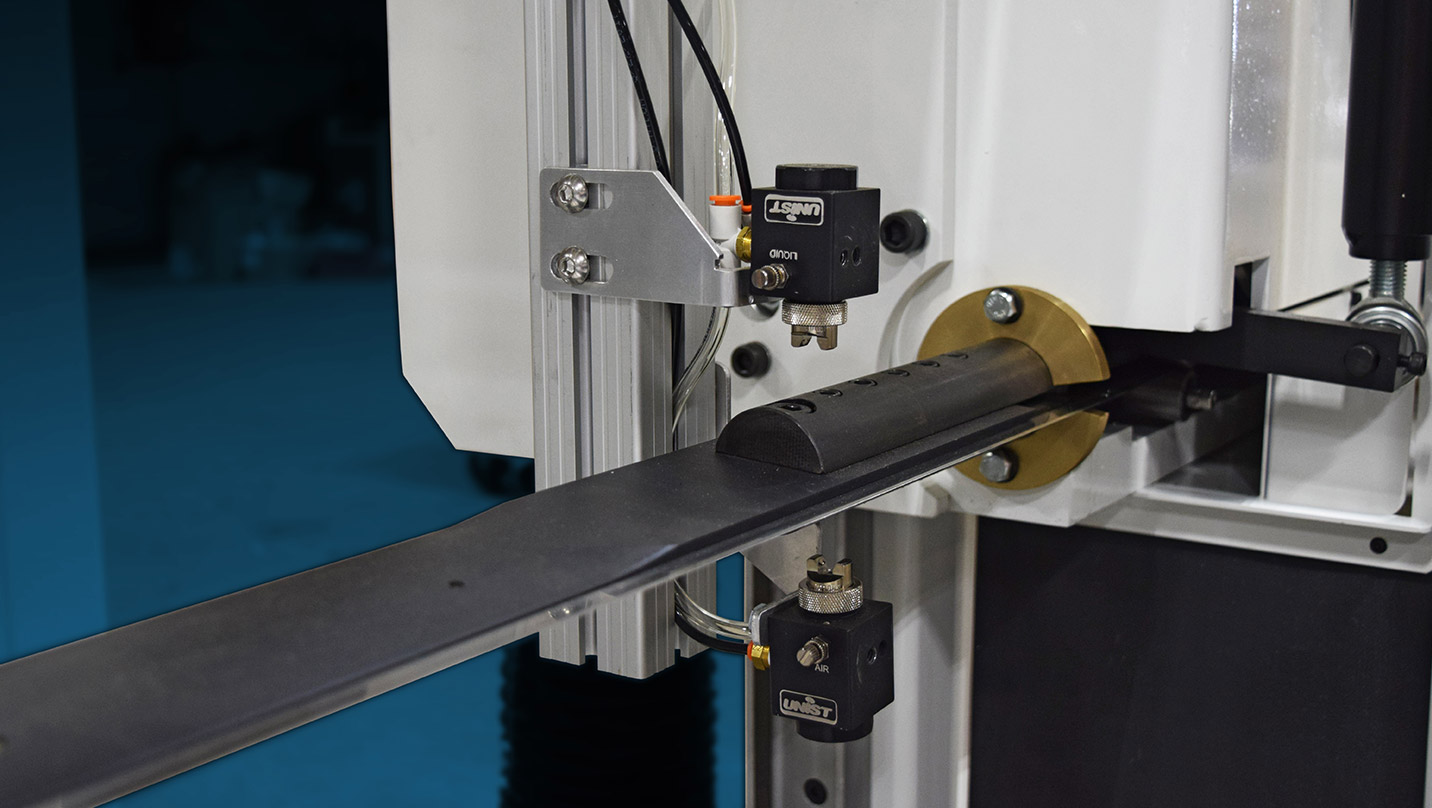

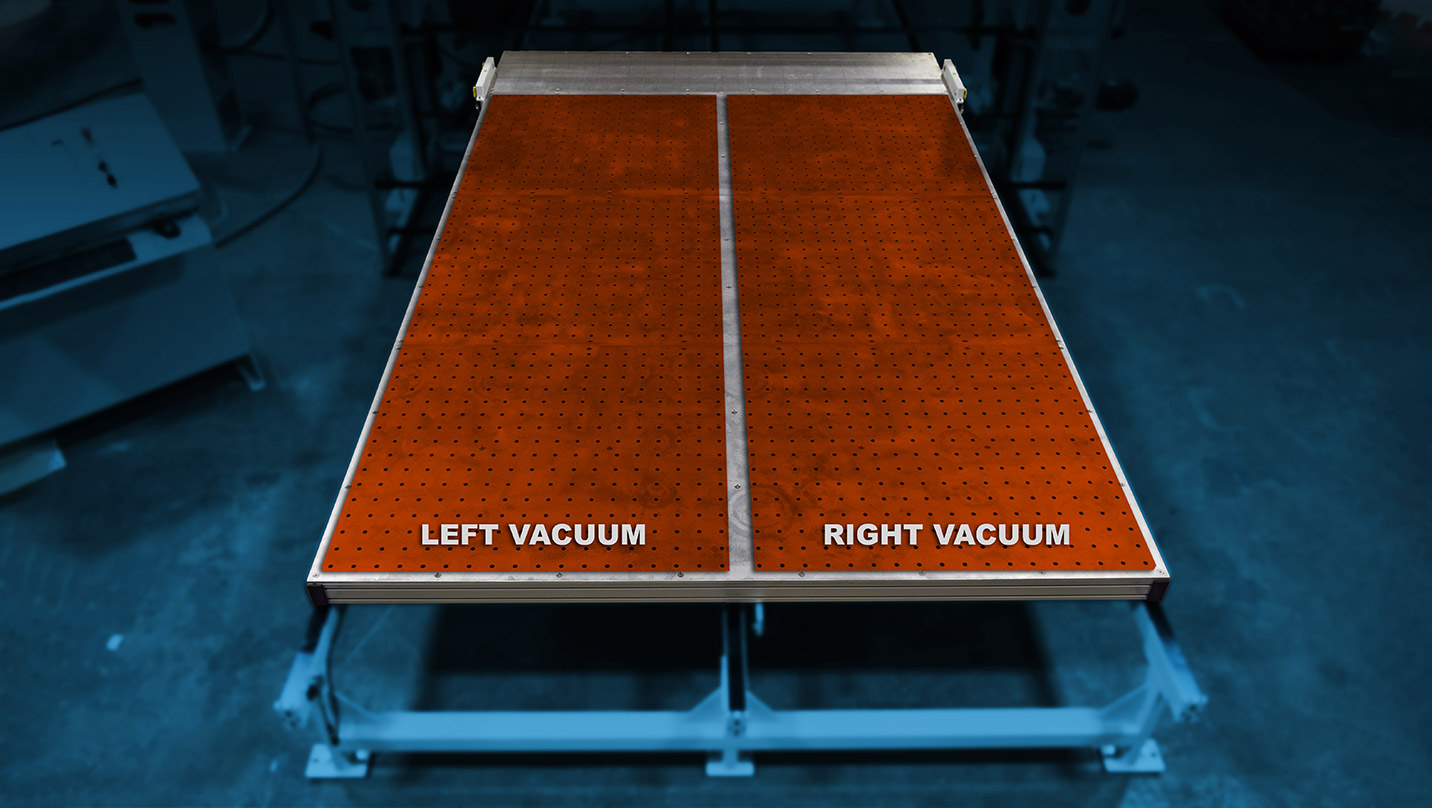

The HTX is equipped with PLC control and an advanced PC touch screen interface with a material database able to save foam processing parameters as well as remote support capabilities. Offered in vacuum table, high speed belts models and carrousel models; the HTX ships standard with programmable blade guide tilting system and selectable vacuum blowers for independent blower control. Advanced options such as a precision blade sharpening system and automated silicone application system further enhance the capabilities of this advanced slitter.

Common Applications

Furniture, Bedding, Packaging, Automotive, Medical

Commonly Processed Materials

PUR-ether and PUR-ester foam, PU rebond foam, reticulated foams, latex, Basotect®, Viscoelastic and similar high-density foams

Download Brochure

HTX Specifications [Downloadable PDF][Opens in New Window]

Descargar folleto

HTX Especificaciones [Descargable PDF][Se abre en ventana nueva]

Operator Controls

Table Assembly

Blade Assembly

Power Requirements

| Specifications | ||||||

|---|---|---|---|---|---|---|

| Models | HTX 51-88 PVT/VBA | HTX 60-88 PVT/VBA | HTX 51-96 PVT/VBA | HTX 60-96 PVT/VBA | HTX-C 51-118 | HTX-C 60-118 |

| Cutting Height | 51 IN [1295 MM] | 60 IN [1524 MM] | 51 IN [1295 MM] | 60 IN [1524 MM] | 51 IN [1295 MM] | 60 IN [1524 MM] |

| Cutting Width | 88 IN [2235 MM] | 96 IN [2438 MM] | 118 IN [2997 MM] | |||

| Cutting Length [HTX Only] | 132 IN [3350 MM] | N/A | ||||

| Table Diameter [HTX-C Only] | N/A | 372 IN [9450 MM] | ||||

| Max Number Of Buns [HTX-C Only] | N/A | 8 | ||||

| Floor Space Required | ||||||

| Overall Width [HTX Only] | 177 IN [4496 MM] | 185 IN [4699 MM] | N/A | |||

| Overall Length [HTX Only] | 283 IN [7188 MM] | N/A | ||||

| Maximum Height | 173 IN [4394 MM] | 191 IN [4851 MM] | 173 IN [4394 MM] | 191 IN [4851 MM] | 173 IN [4394 MM] | 191 IN [4851 MM] |

Subscribe to our newsletter to keep up with the latest news + events