Please refresh page if loading fails

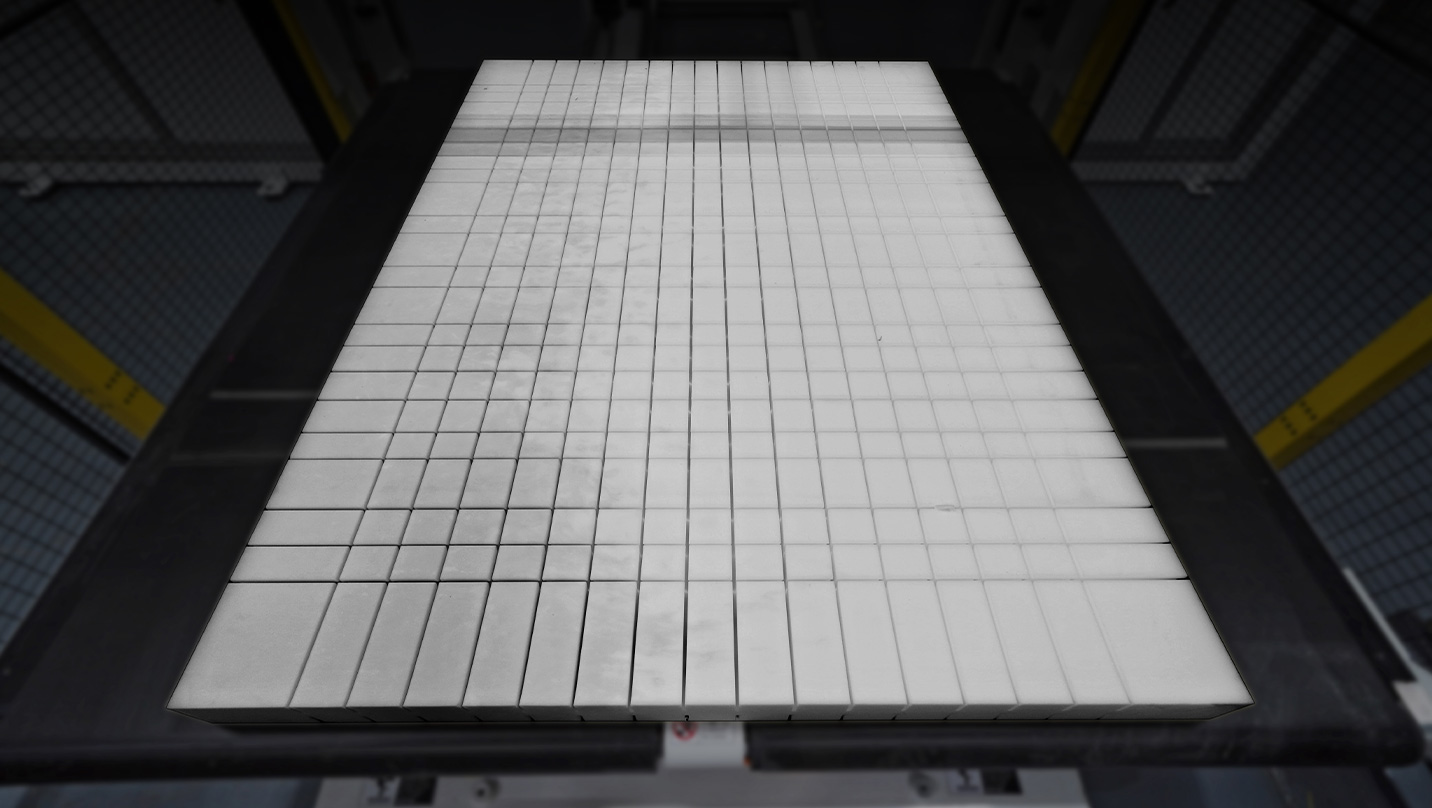

ESCO’s Third-Generation Horizontal Profiler (HPX); Utilizes a continuous blade band knife or tooth blade for fast and accurate profile cutting of flexible polyurethane foams, viscoelastic memory foam, latex foam, and semi-rigid high ILD PU foam.

Overview

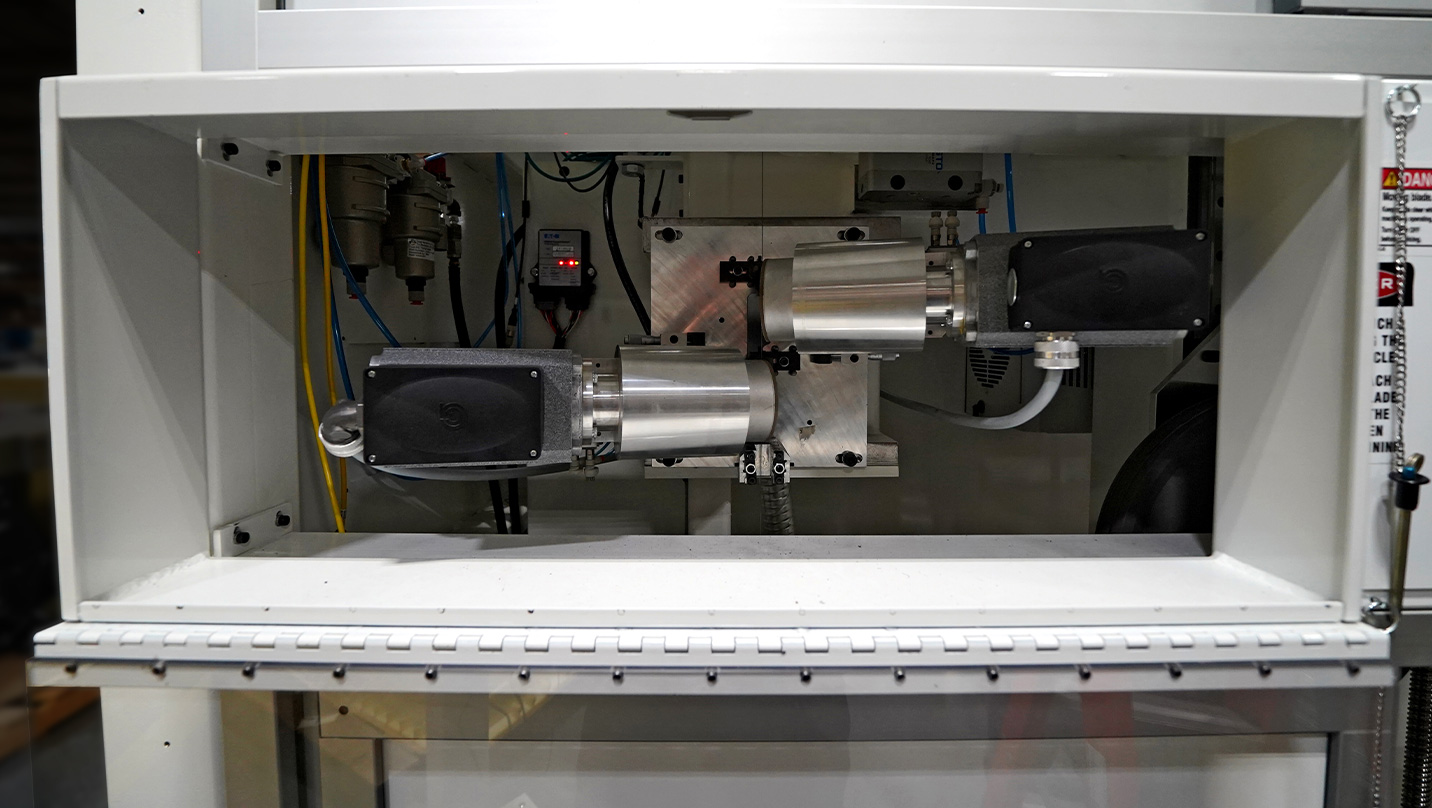

ESCOs Third-generation horizontal profiler [HPX]; Utilizes a rigid, welded steel frame with a revised head design that employs a movable pulley system. The revised system is a departure from traditional four pulley moving head designs seen in use today.

The new footprint of the machine and safety guarding enhances the usability of the HPX by placing the operator closer to the cutting area and workpiece. This allows for faster job setup, more accurate blade alignment and quality control of the workpiece.

The horizontal contour foam saw has many applications and options making it a very versatile foam fabrication machine. ESCO’s horizontal blade CNC foam saw is most commonly used in furniture, bedding, packaging, medical, automotive and aerospace industries.

Common Applications

Bedding, furniture, packaging, medical, insulation, automotive, aerospace

Commonly Processed Materials

PUR soft foam, PUR HR foam, viscoelastic foam, latex, leightweight rebond foams, Basotect®

Download Brochure

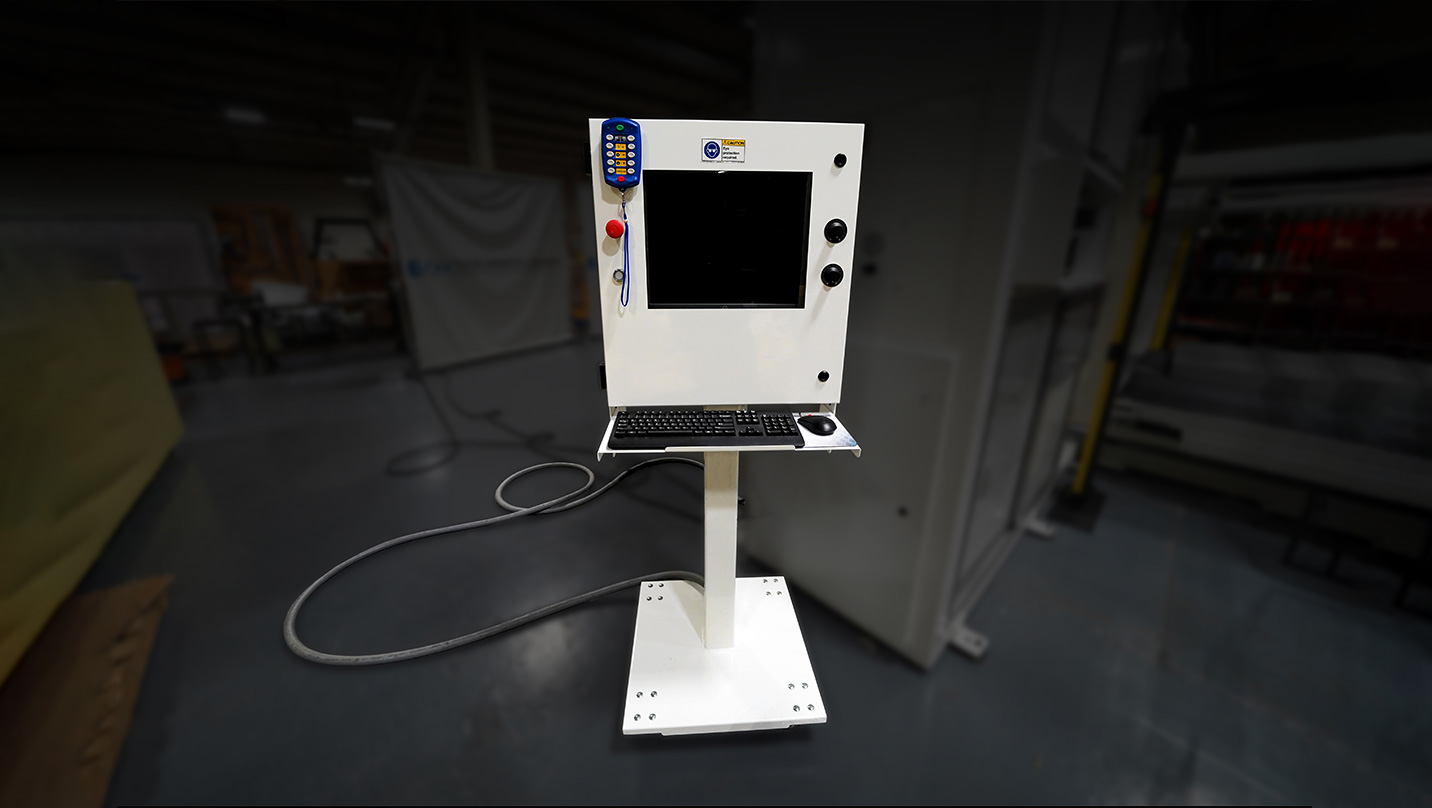

Operator Controls

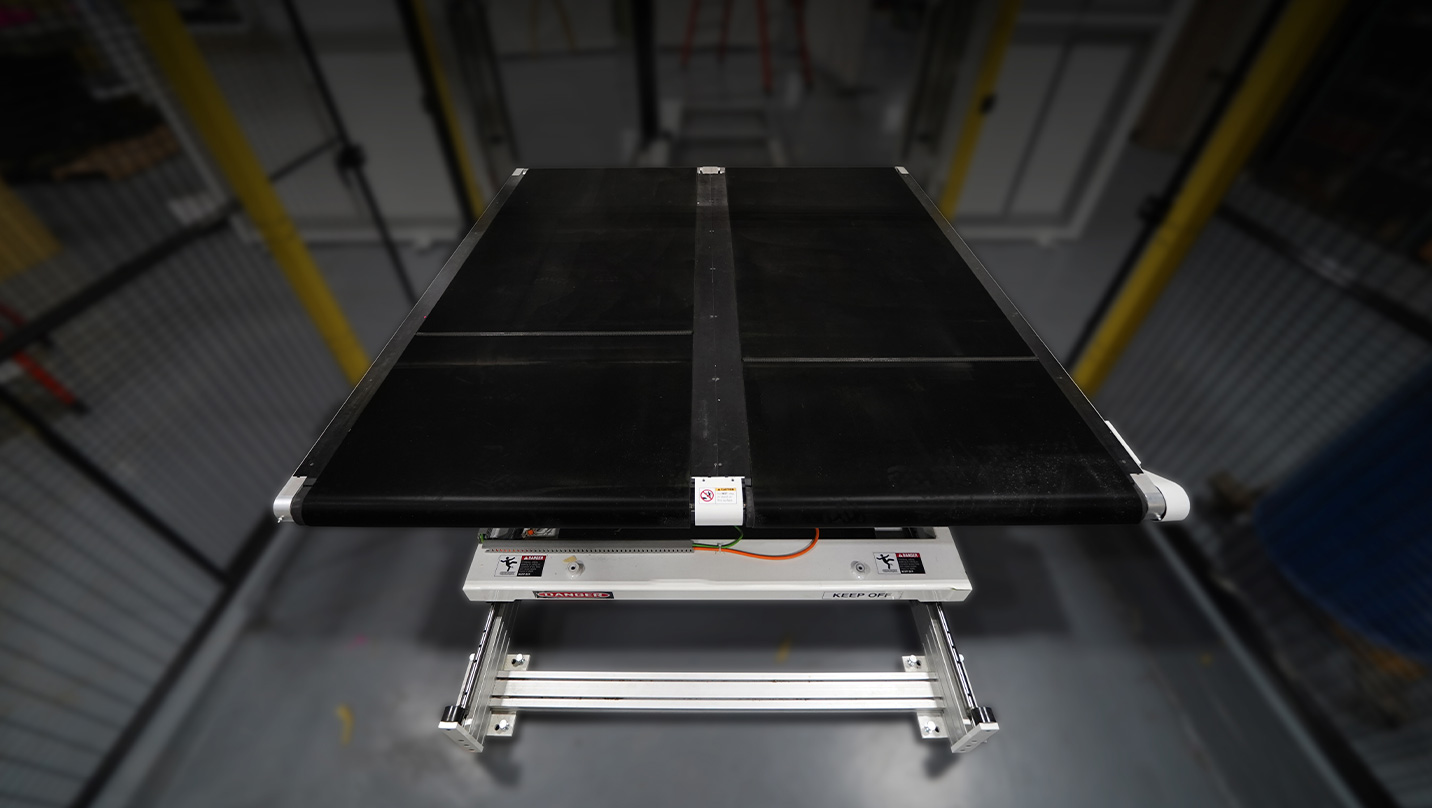

Hold-Down + Center-Guide Assembly

Power Requirements

| Specifications | ||

|---|---|---|

| Model | HPX 50-88 | HPX 60-88 |

| Blade Speed | Variable | Variable |

| Cutting Speed | 180 FT/MIN [55 M/MIN] | 180 FT/MIN [55 M/MIN] |

| Cutting Width | 86.8 IN [2200 MM] | 86.8 IN [2200 MM] |

| Cutting Height | 51.2 IN [1300 MM] | 61.2 IN [1554 MM] |

| Floor Space Required | ||

| Overall Width | 229 IN [5817 MM] | N/A |

| Overall Length | 297 IN [7544 MM] | N/A |

| Overall Height | 110 IN [2794 MM] | N/A |

| shipping weight : HPX 50-88 Model - 8,000 lbs [3,629 kg] [varies by model/options] | ||

Subscribe to our newsletter to keep up with the latest news + events