Overview

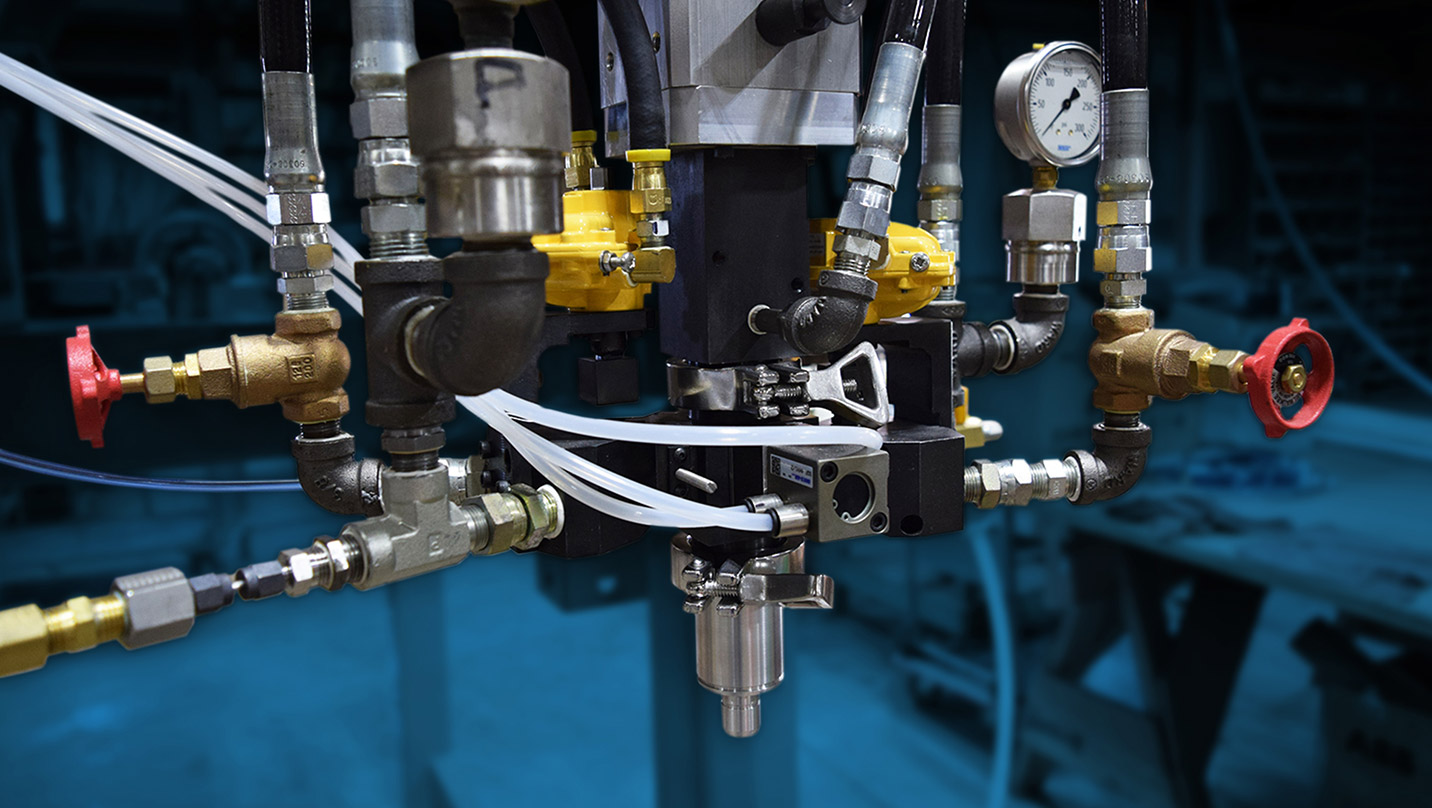

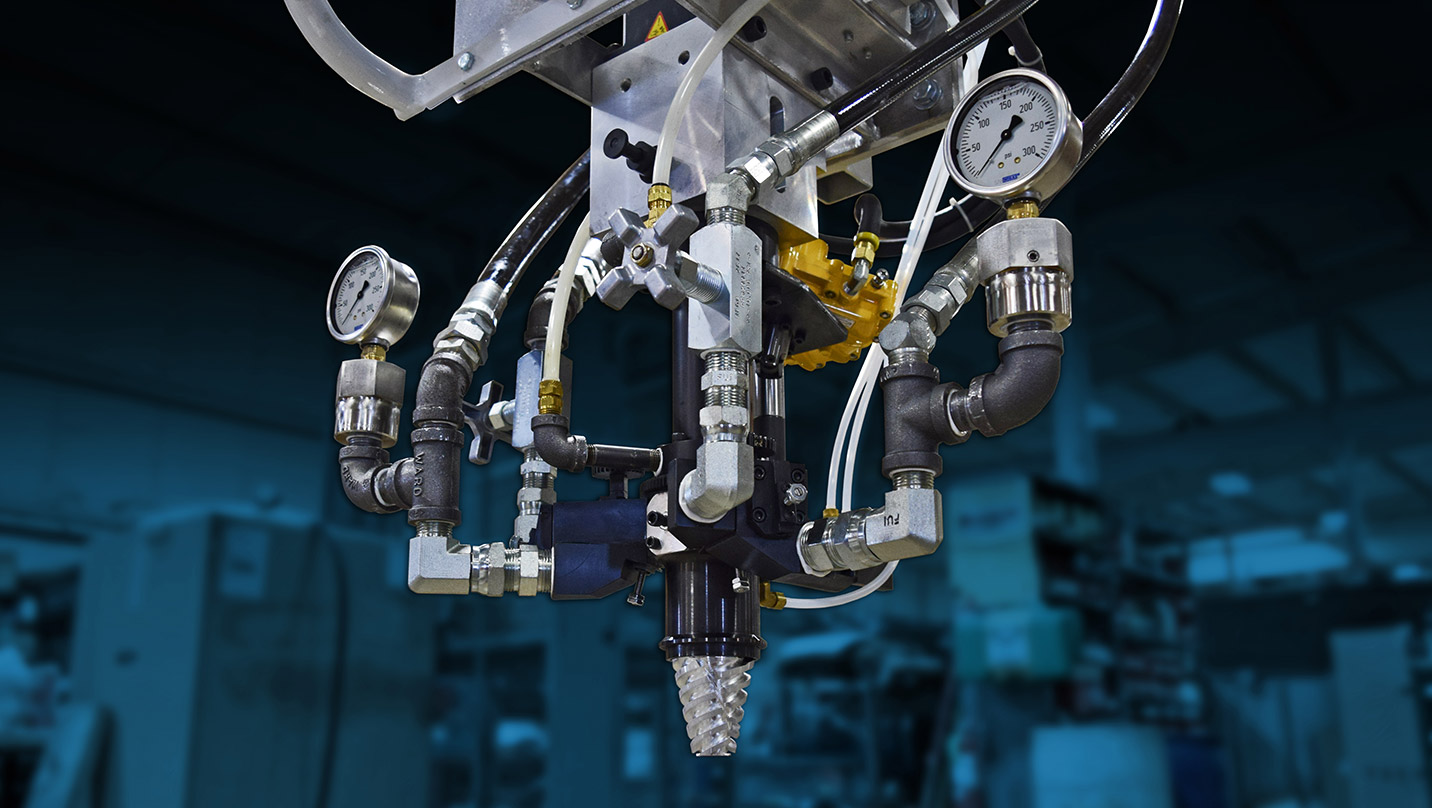

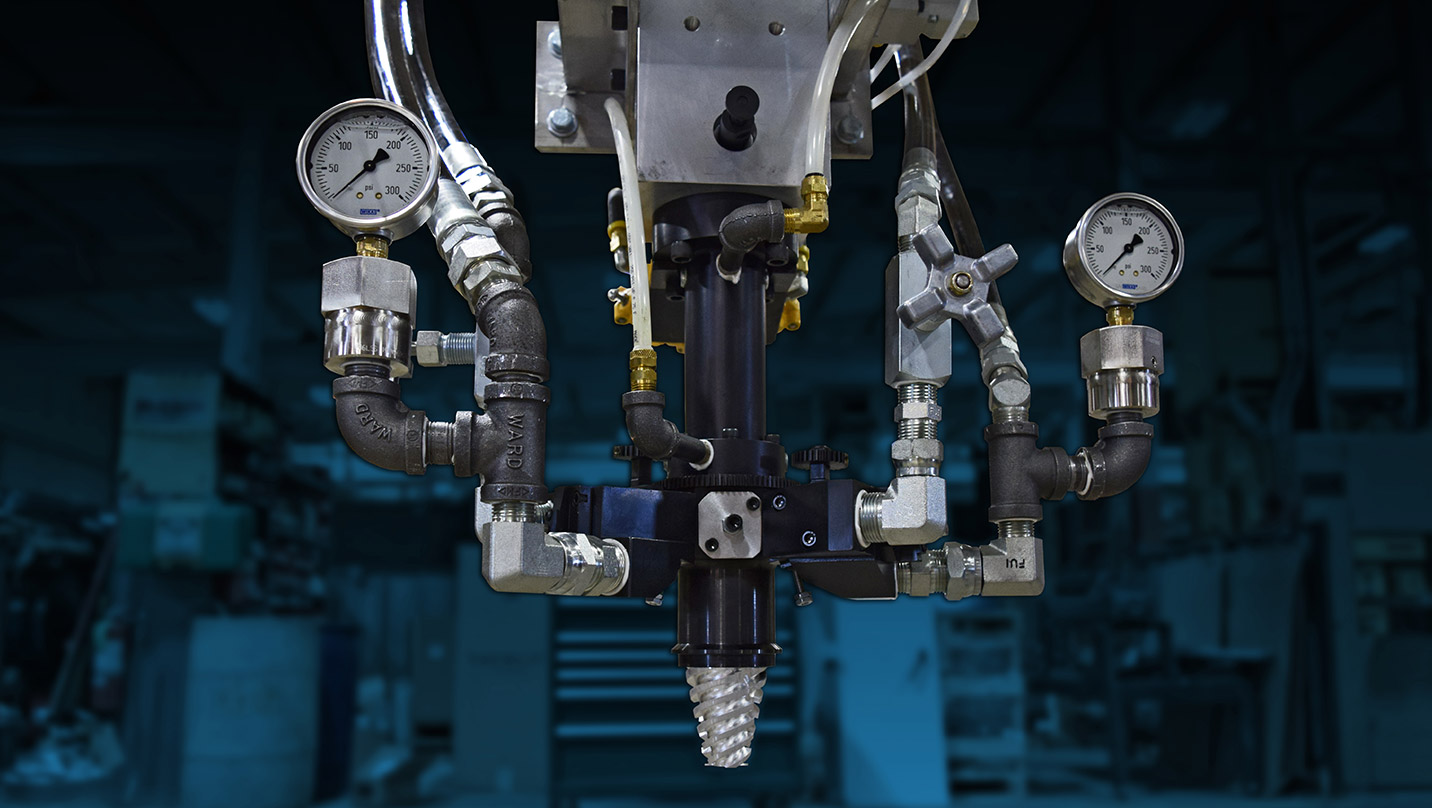

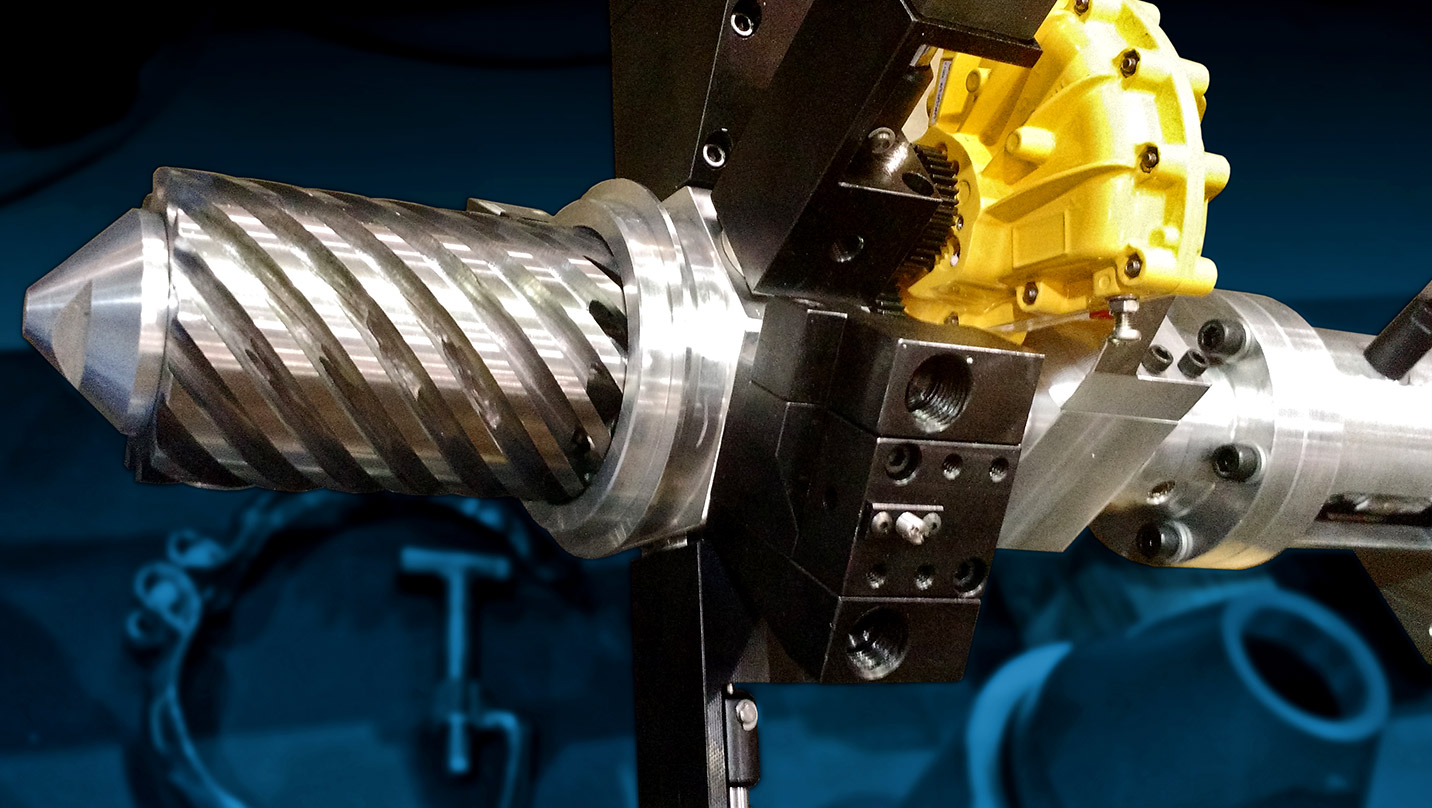

ESCO mixing heads feature a modular design that allows production and application flexibility, improved maintainability and ease of customization to fit any polyurethane process application.

M-Series mixheads incorporate external valving and porting, which allows calibration without removal of the impeller.

Custom Application Mixing Heads

ESCO produces custom engineered mixing heads for any number of special or difficult to process applications including:

Mixhead Model Features

- M-100

Output LBS/MIN : .25-3

Number of Components : 2-3

MAX Speed RPM : 6000

- M-200

Output LBS/MIN : 1-20

Number of Components : 2-3

MAX Speed RPM : 6000

- M-500

Output LBS/MIN : 5-70

Number of Components : 2-5

MAX Speed RPM : 5000

- M-800

Output LBS/MIN : 30-150

Number of Components : 2-6

MAX Speed RPM : 5000

- M-900

Output LBS/MIN : 50-300

Number of Components : 2-6

MAX Speed RPM : 5000

- M-1000

Output LBS/MIN : 100-600

Number of Components : 2-6

MAX Speed RPM : 4000

- M-1100

Output LBS/MIN : 200-1000

Number of Components : 2-6

MAX Speed RPM : 4000

M-100

Mixing Head

Standard Features

- Output range: .25-3 lb./min. (2-23 grams/sec)

- 2 or 3 components

- External calibration porting

- Adjustable orifices

- 1000-7000 RPM

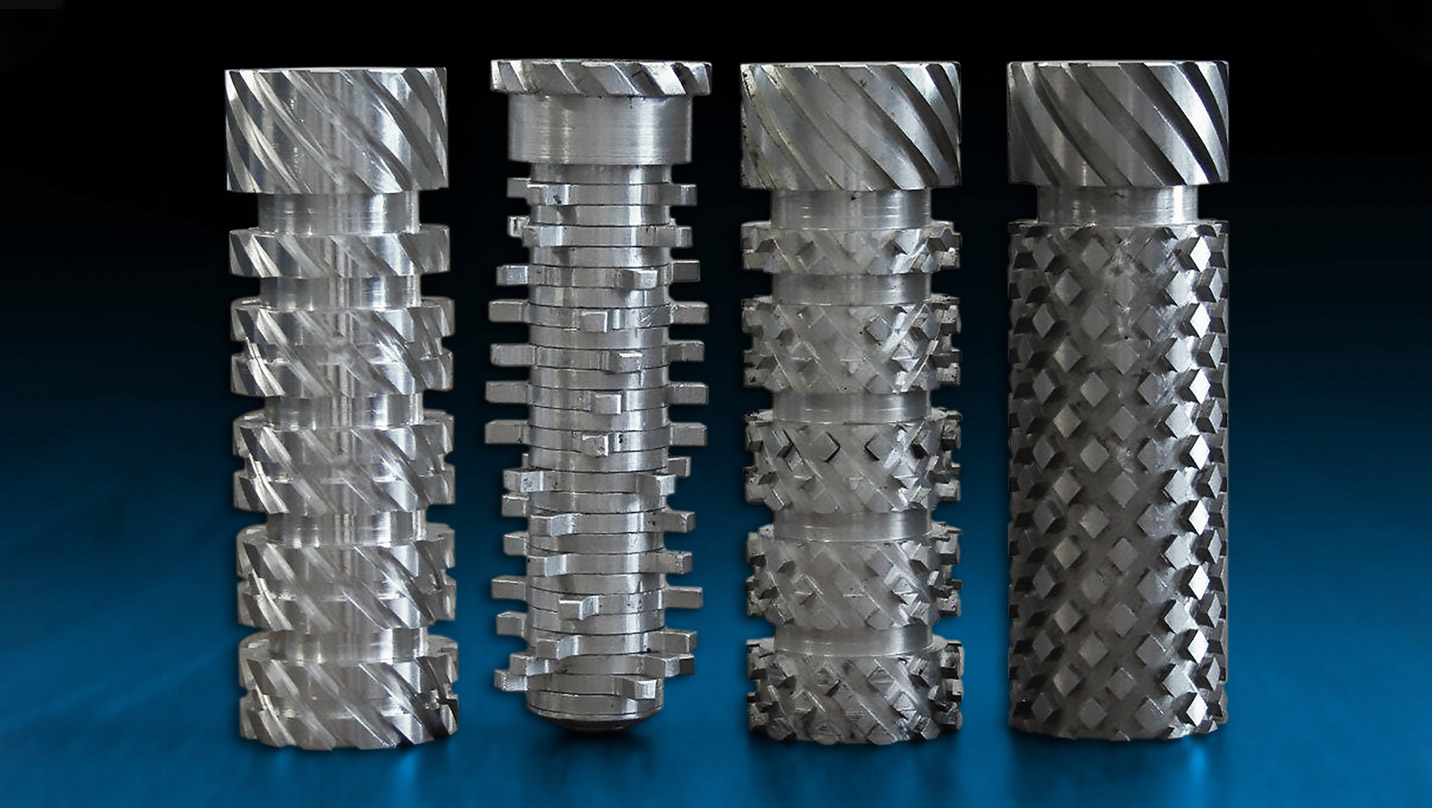

- Multiple mixer styles for any application

Optional Features

- Stainless steel wetted parts

- Heated valves

- Servomotor drive for multi-axis in-situ gasketing, automated molding or similar applications

- Continuous pour version

M-200

Mixing Head

Standard Features

- Output range: 1-20 lb./min. (7-150 grams/sec)

- 2 or 3 components

- External calibration porting

- Adjustable orifices

- 1000-6000 RPM

- Multiple mixer styles for any application

- Elastomer, foam and continuous pour versions

Optional Features

- Up to 5 components optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Servomotor drive for multi-axis in-situ gasketing, automated molding or similar applications

M-500

Mixing Head

Standard Features

- Output range: 3-70 lb./min. (23-530 grams/sec)

- 2-6 Components Standard

- External calibration porting

- Adjustable orifices

- 1000-5000 RPM

- Lip or mechanical shaft seal versions

- Multiple mixer styles for any application

- Elastomer, foam and continuous pour versions

Optional Features

- Up to 10 components Optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Servomotor drive for multi-axis in-situ gasketing, automated molding or similar applications

M-800

Mixing Head

Standard Features

- Output range: 30-150 lb./min. (227-1134 grams/sec)

- 2-6 Components Standard

- Adjustable orifices

- 1000-5000 RPM

- Mechanical shaft seal

- Multiple mixer styles for any application

- Elastomer, foam and slab/sheet stock processing versions

Optional Features

- Up to 10 components Optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Hydraulic drive for continuous port/traversing applications

M-900

Mixing Head

Standard Features

- Output range: 50-300 lb./min. (378-2268 grams/sec)

- 2-6 Components Standard

- Adjustable orifices

- 1000-5000 RPM

- Mechanical shaft seal

- Multiple mixer styles for any application

- Elastomer, foam and slab/sheet stock processing versions

Optional Features

- Up to 10 components Optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Hydraulic drive for continuous port/traversing applications

M-1000

Mixing Head

Standard Features

- Output range: 100-600 lb./min. (756-4536 grams/sec)

- 2-6 Components Standard

- Adjustable orifices

- 1000-4000 RPM

- Mechanical shaft seal

- Multiple mixer styles for any application

- Elastomer, foam and slab/sheet stock processing versions

Optional Features

- Up to 10 components Optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Hydraulic drive for continuous port/traversing applications

M-1100

Mixing Head

Standard Features

- Output range: 200-1000 lb./min. (1512-7560 grams/sec)

- 2-6 Components Standard

- Adjustable orifices

- 1000-4000 RPM

- Mechanical shaft seal

- Multiple mixer styles for any application

- Elastomer, foam and slab/sheet stock processing versions

Optional Features

- Up to 10 components Optional

- More components with custom applications including multiple color injectors

- Stainless steel wetted parts

- Heated valves

- Jacketed mixer nozzles

- Hydraulic drive for continuous port/traversing applications