Please refresh page if loading fails

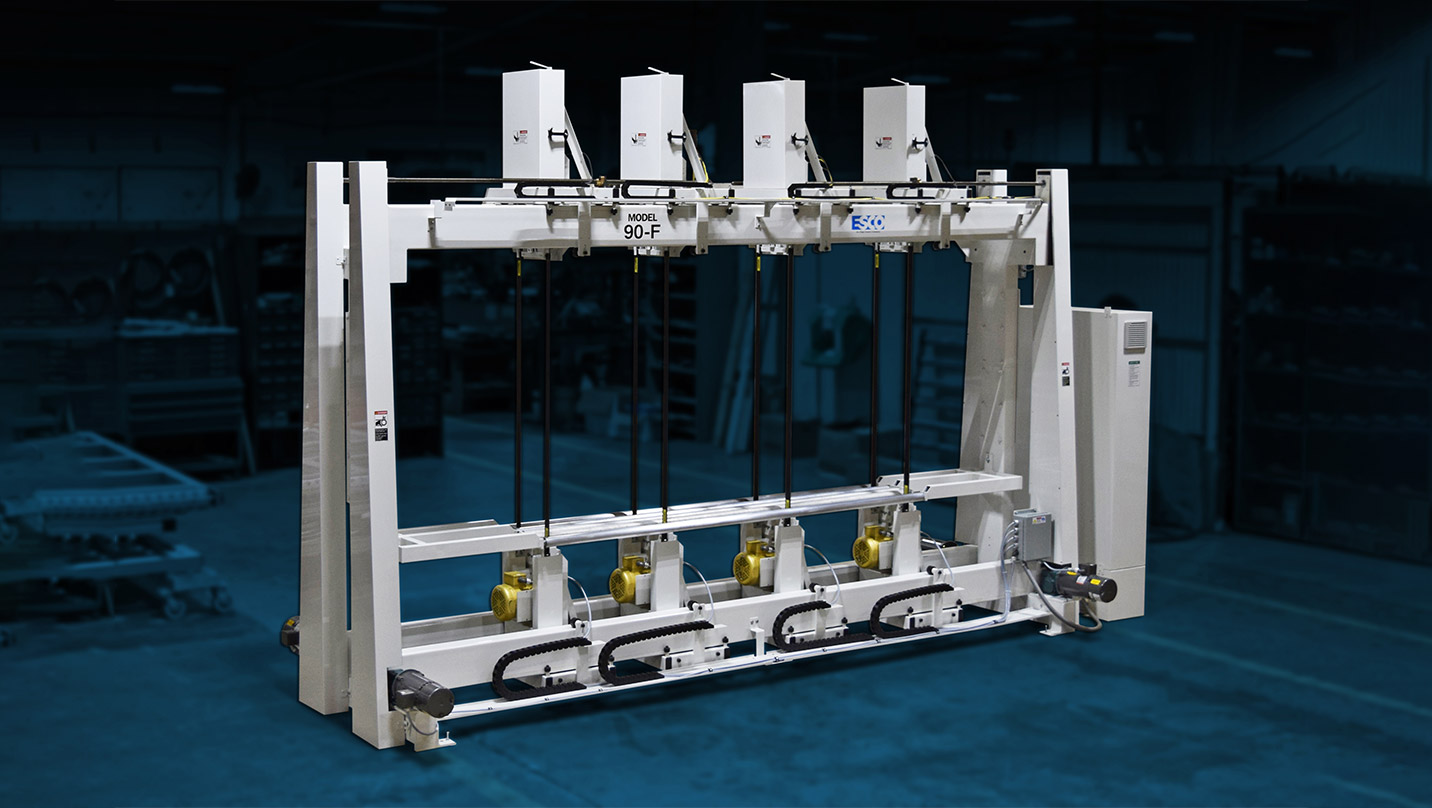

ESCO's Model 90-F side trimmer and subdivider is used with a conveyor and can subdivide a flexible polyurethane bun in up to three individual sections.

LEGACY MACHINE

Legacy machinery is not available for quotation.

Edge-Sweets is currently modernizing our legacy machines utilizing state-of-the-art manufacturing processes to offer high-quality, modern machines at a competitive price. Your sales engineer will have more information when legacy machines will be available for quotation again.

Overview

The ESCO Model 90 is a 2, 3, or 4 head machine designed to integrate into a conveyor line to trim the edges of foam buns or slab lines. The additional heads allow the user to subdivide the trimmed bun into narrower sections, making this an ideal machine for mattress, packaging, and furniture applications.

Common Applications

Furniture, bedding, mattresses, upholestry, automotive and packaging

Commonly Processed Materials

PUR-ether and polyester, HR, CMHR, viscoelastic, flexible and other similar materials

Download Brochure

Model 90 Specifications [Downloadable PDF][Opens in New Window]

Operator Controls

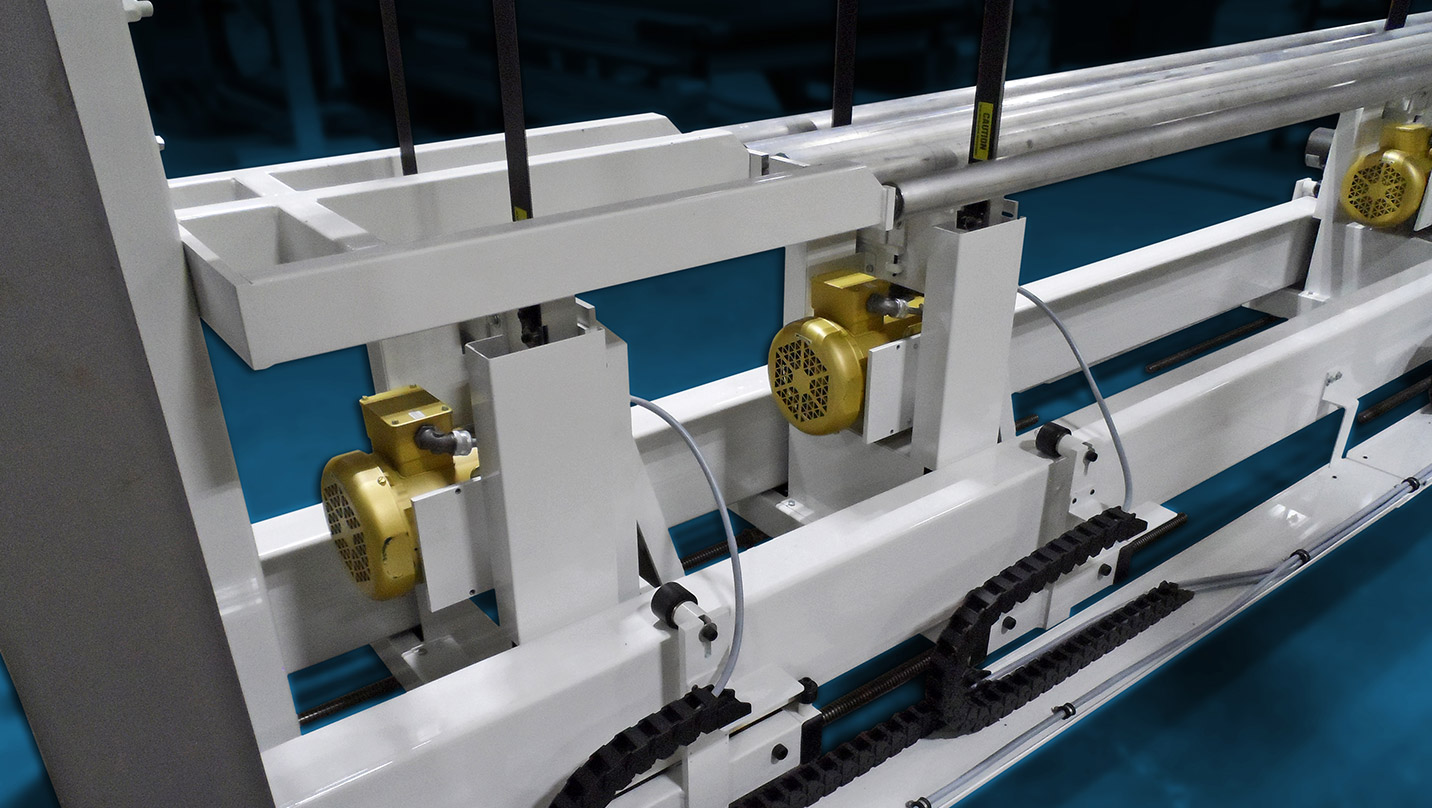

Head Assembly

Table Assembly

Blade Assembly

Power Requirements

| Specifications | |||

|---|---|---|---|

| Models | 90-F-40 | 90-F-50 | 90-F-60 | Cutting Height | 40 IN [1016 MM] | 50 IN [1270 MM] | 60 IN [1524 MM] |

| Cutting Width - Minimum | 16 IN [406 MM] | ||

| Cutting Width - Maximum | 90 IN [2286 MM] | ||

| Floor Space Required | |||

| Overall Width | 65 IN [1651 MM] | ||

| Overall Length | 2 Heads - 140 IN [3556 MM], 4 Heads - 170 IN [4318 MM] | ||

| Maximum Height | 108 IN [2743 MM] [Minimum], 130 IN [3302 MM] [Maximum] | ||

| Shipping Weight : 2500-4500 LBS [1134-2041 KG] [Varies By Model/Options] | |||

Subscribe to our newsletter to keep up with the latest news + events