DML General Specifications

- 3-Way valves for material injection and recirculation

- Plunger style solvent injector valve

- Spiral gear mixer and threaded outlet nozzle

- Mechanical-type shaft seal with static bearing lubrication

- Servo-motor drive with variable speed control

- 1000-6000 RPM Speed range

- Return line valves for pressure balancing

Optional Features

- Automatic Flush with manual backup

- Tank Agitation - Fixed Speed Electric

- Heat - 175 F (80 C) Temperature Limit - Electrically heated tank, supply and return hoses, tank agitation included

- Flow Meter - Positive displacement gear or helical gear

- Upgrade Wetted Parts - Stainless Steel

- Custom options available upon request

Operator Controls

- Allen Bradley PLC mounted to front panel of machine

- Operator Interface Terminal

- Mixing Head Operator buttons

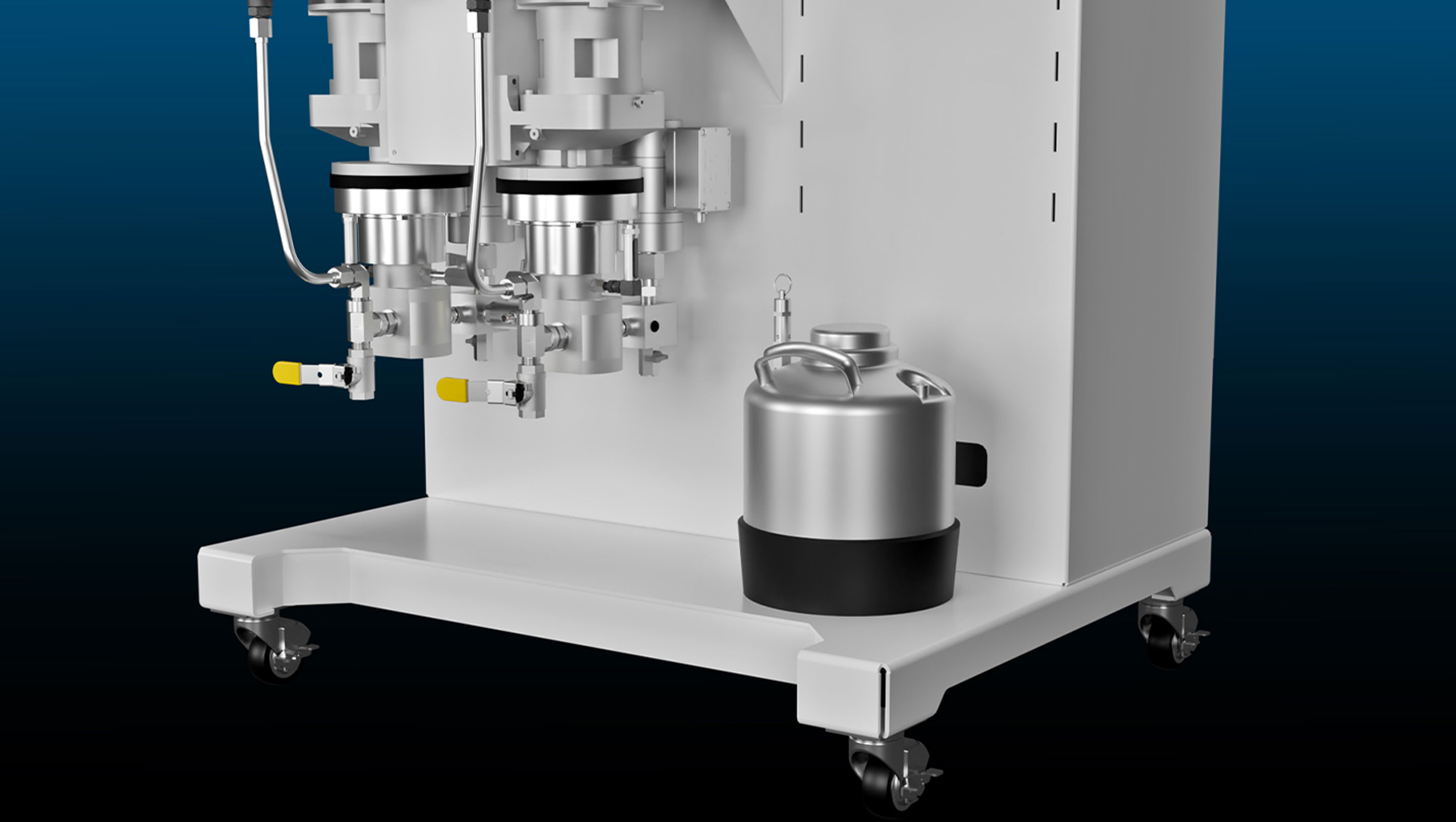

Solvent Flush System

- 2-Gallon (7.5L) Stainless tank rated to 100 PSI

- Blanket pressure regulator with relief and shutoff valving

- Reinforced nylon supply hose to mixing head

- Recommened Solvent : DBE or similar

- Manual operation with optional automatic

Component Specifications

- A-Comp Viscosity : 3,000 CPS @ 75 F (24 C)

- B-Comp Viscosity : 3,000 CPS @ 75 F (24 C)

- Pumps: Gear

- Speed Control : Variable AC (1/4 HP)

- A-Comp Strainer : 100 Mesh

- B-Comp Strainer : 60 Mesh

- Wetted Parts : Carbon Steel Standard

- Elastomers : Teflon, Silicone, or EPDM

Power Requirements

- Power : 480V / 3P / 60Hz

- Compressed Air : 90-100 PSI @ 10 SCFM

- Nitrogen : > 20 PSI @ 20 CFM or Dry Air @ 40F (5C) Dew Point or better

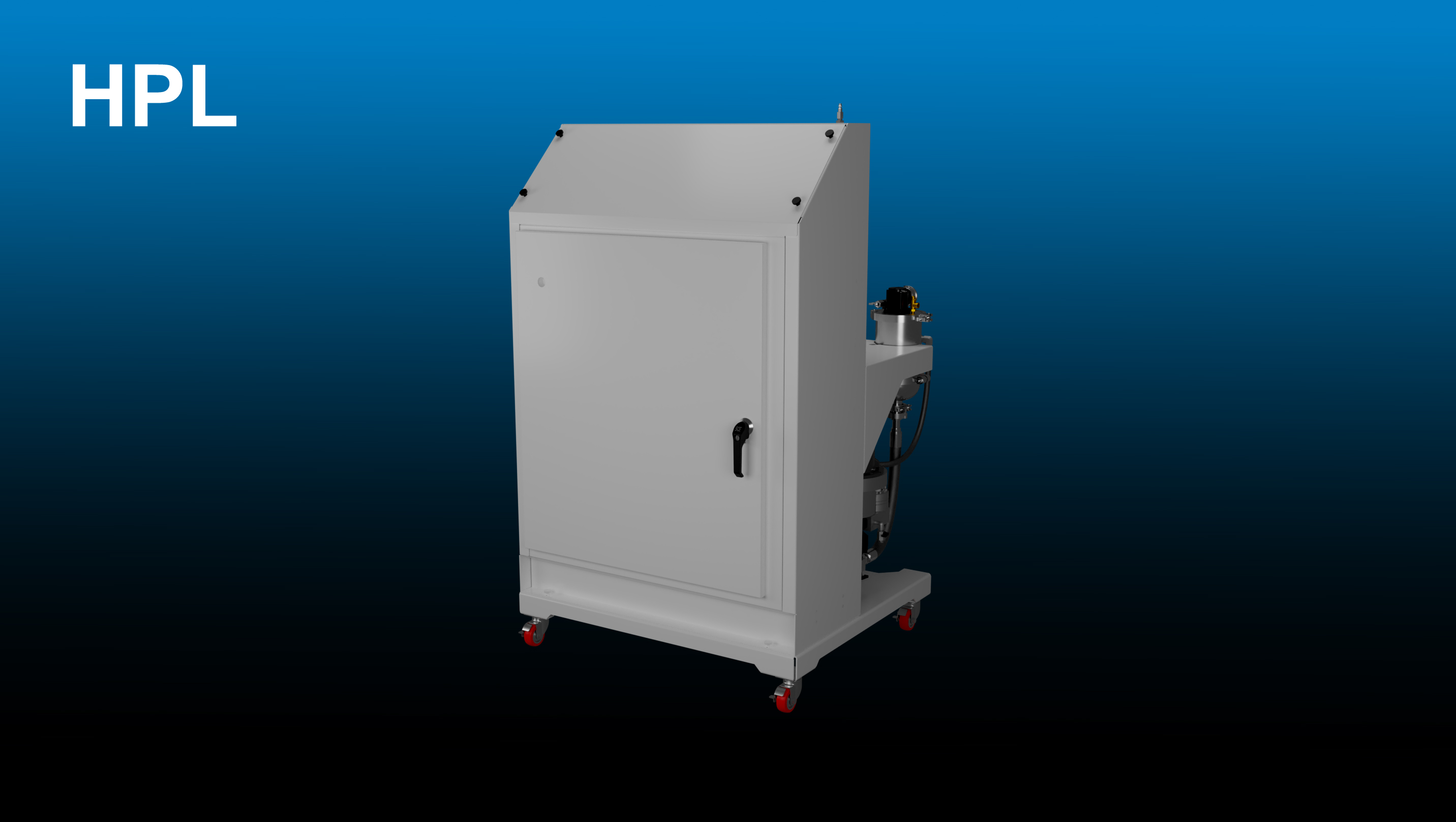

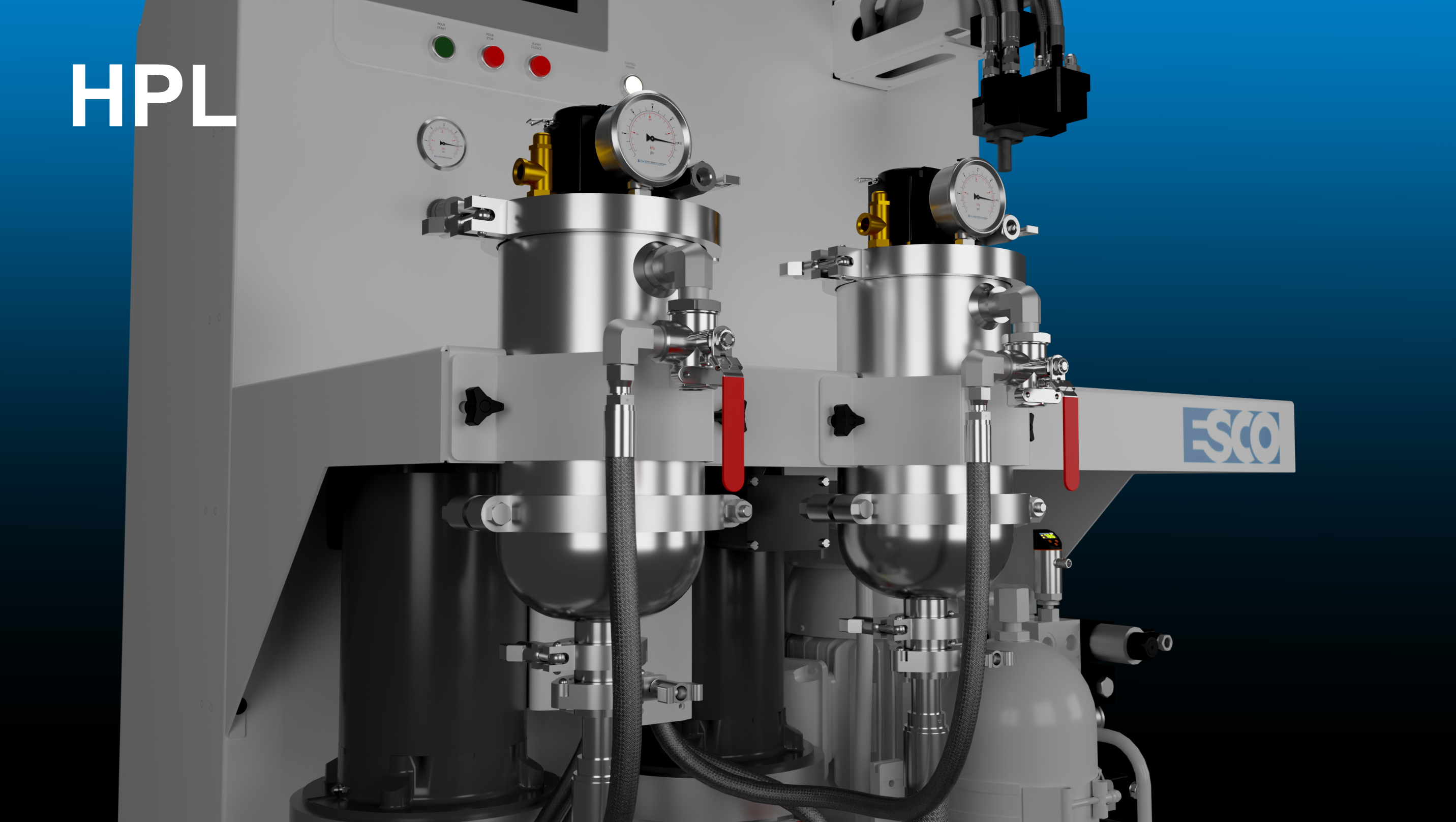

HPL General Specifications

- Double Tilted Rear Chamber Mixing System

- Anti stick locking design

- Mechanical stroke adjustment

- Includes single set of adjustable mixing nozzles sized to material being mixed

- Minimum 10-second dwell between shots

Optional Features

- Automatic Flush with manual backup

- Tank Agitation - Fixed Speed Electric

- Heat - 175 F (80 C) Temperature Limit - Electrically heated tank, supply and return hoses, tank agitation included

- Flow Meter - Positive displacement gear or helical gear

- Upgrade Wetted Parts - Stainless Steel

- Custom options available upon request

Operator Controls

- Allen Bradley PLC mounted to front panel of machine

- Operator Interface Terminal

- Mixing Head Operator buttons

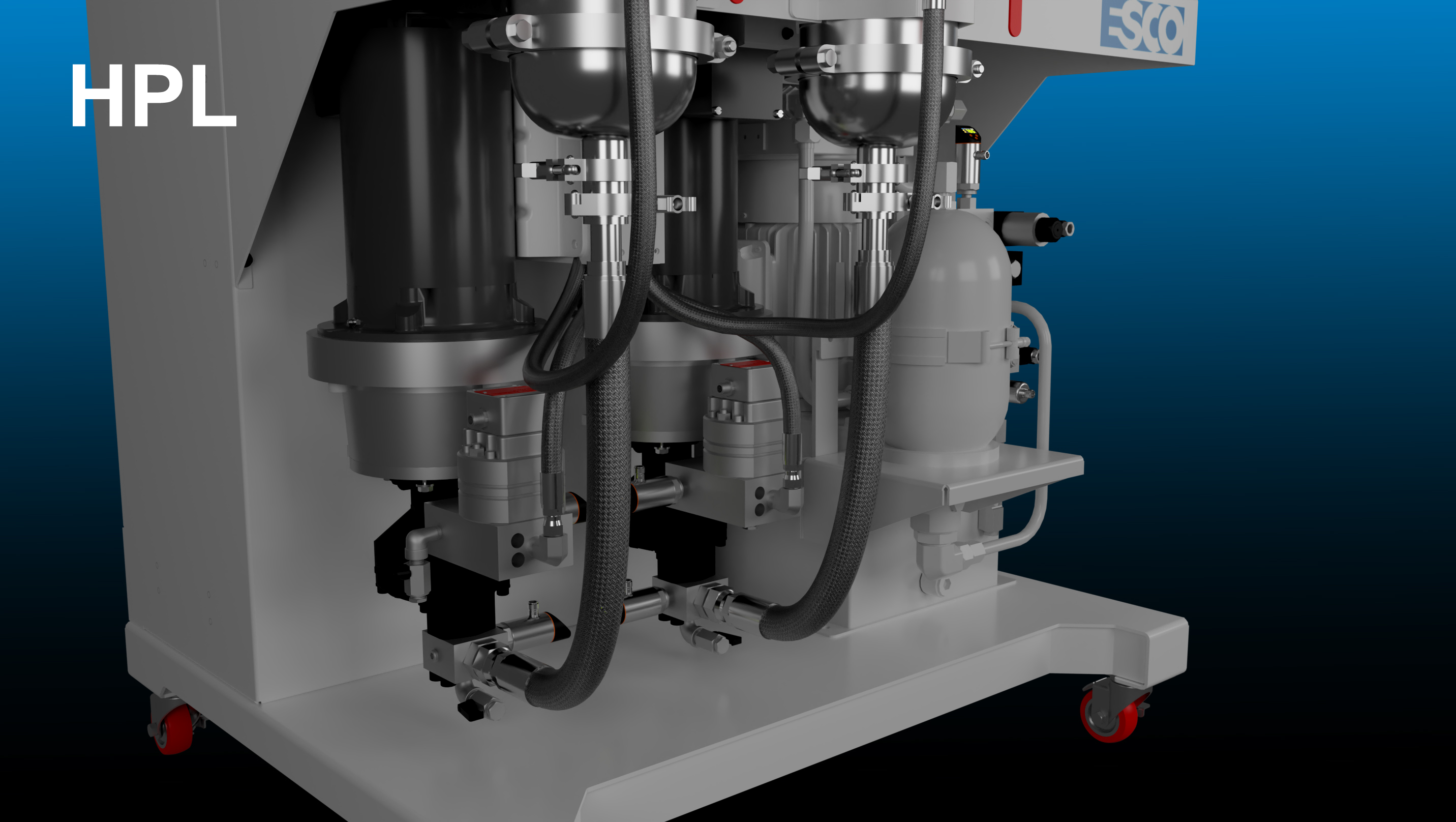

Hydraulic Power Unit

- 5 HP variable speed motor to ramp down the motor speed to conserve energy and reduce heat generation

- 1-gallon bladder type accumulator

- 5-gallon fluid reservoir with air-cooled heat exchanger

Component Specifications

- A-Comp Viscosity : 2,000 CPS @ 75 F (24 C)

- B-Comp Viscosity : 2,000 CPS @ 75 F (24 C)

- Pumps: Fixed Displacement Rotary Piston

- Speed Control : Variable AC (3 HP)

- Filtration : 100 Micron

- Wetted Parts : Carbon Steel Standard

- Elastomers : Teflon, Silicone, or EPDM

Power Requirements

- Power : 480V / 3P / 60Hz

- Compressed Air : 90-100 PSI @ 10 SCFM

- Nitrogen : > 20 PSI @ 20 CFM or Dry Air @ 40F (5C) Dew Point or better

| MODEL |

DML-2 |

DML-5 |

DML-10 |

HPL-10 |

| OUTPUT |

0.4 - 2.0 LB/MIN |

0.5 - 5.0 LB/MIN |

2.0 - 10.0 LB/MIN |

4.0 - 10.0 LB/MIN |

| RATIO |

1:5 to 1:1 to 5:1 |

| TANK CAPACITY |

1 QT |

2 QT |

1-2 GAL |

1-2 GAL |

| MIXING HEAD |

M-100 |

M-100 |

M-200 |

DTRC-0608 |