Please refresh page if loading fails

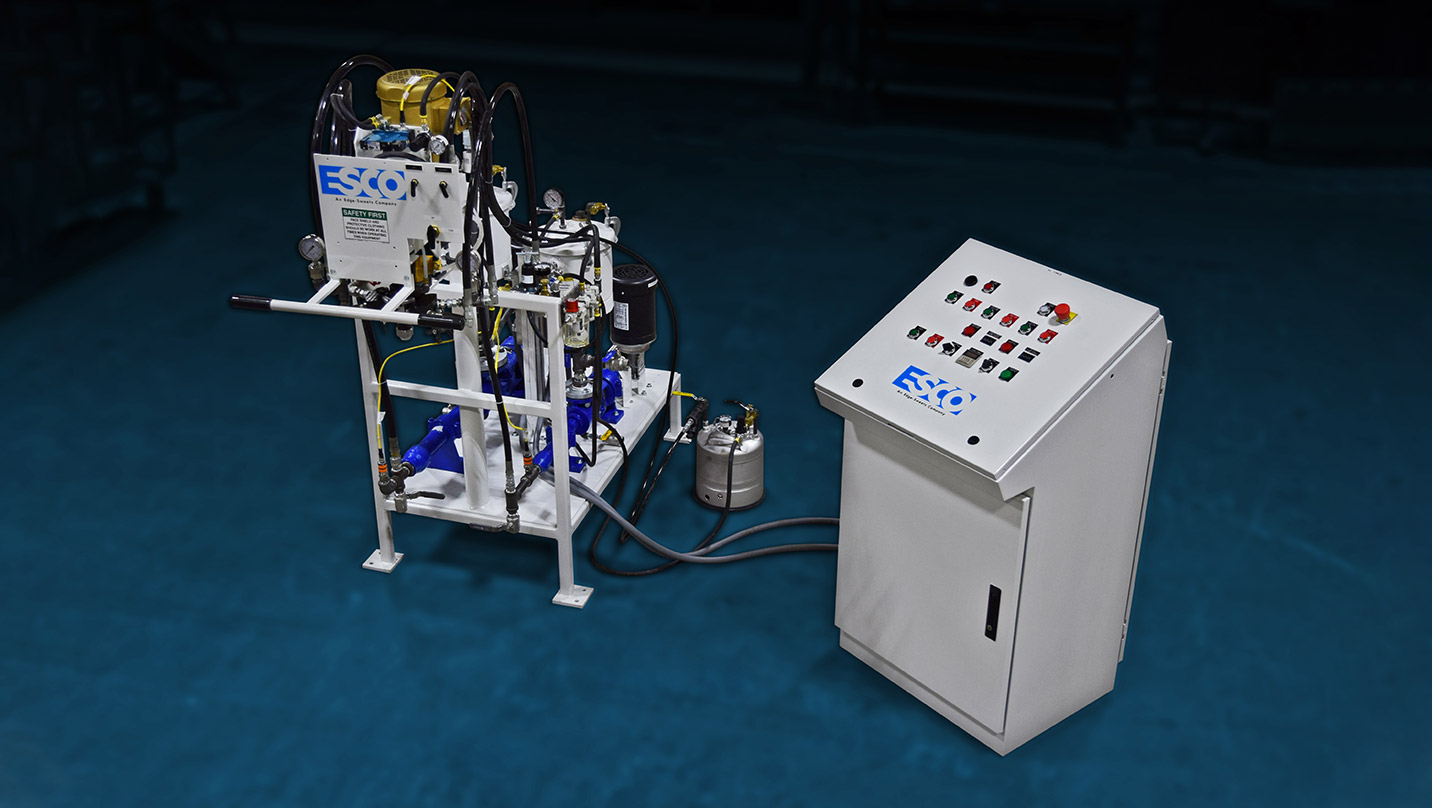

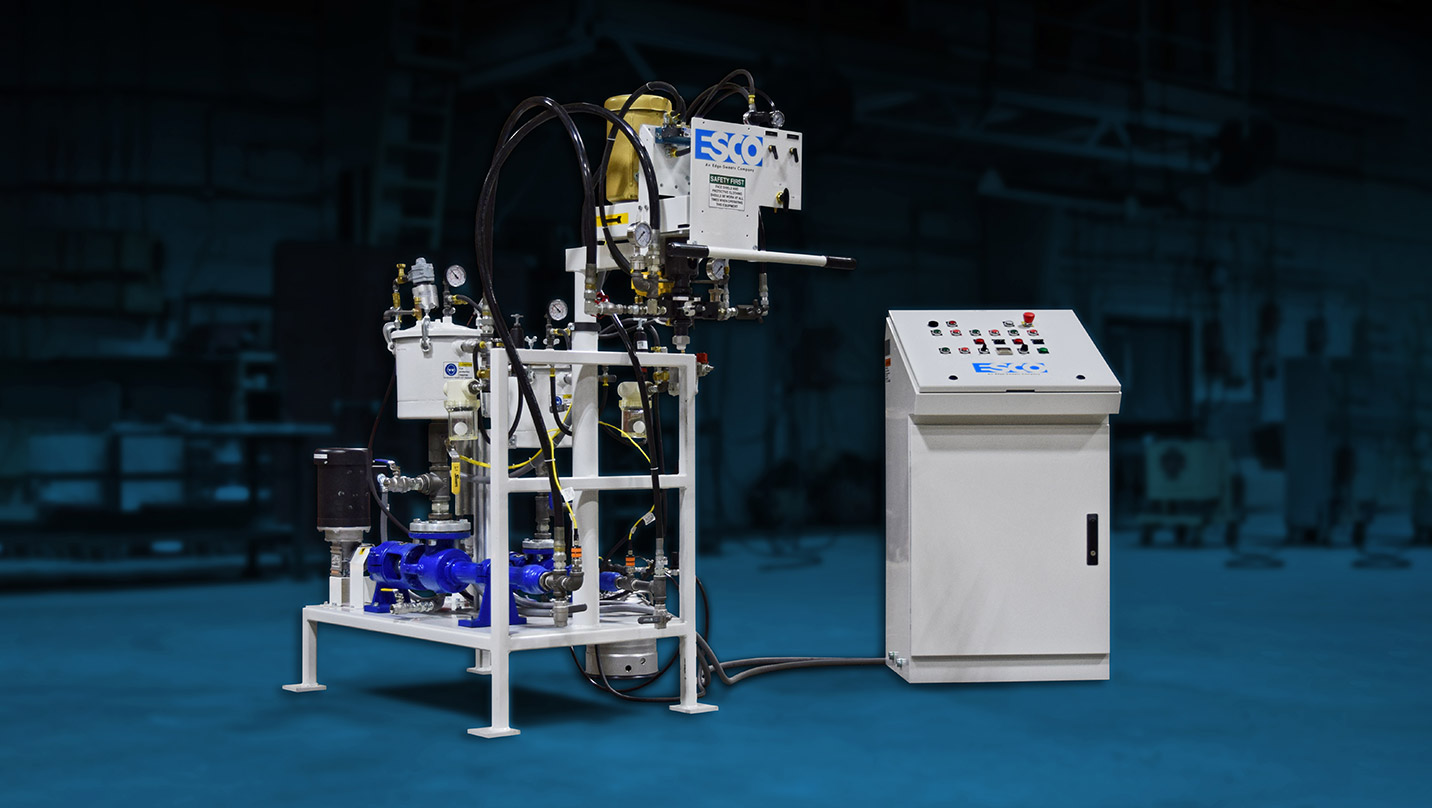

ESCO offers patented solutions for dynamically metering and mixing dry fillers into PU systems. From syntactic elastomeric coatings for deep sea oil pipe to green automotive PU systems that utilize recycled ground tire ESCO has 30+ years of advanced filler processing technology.

Overview

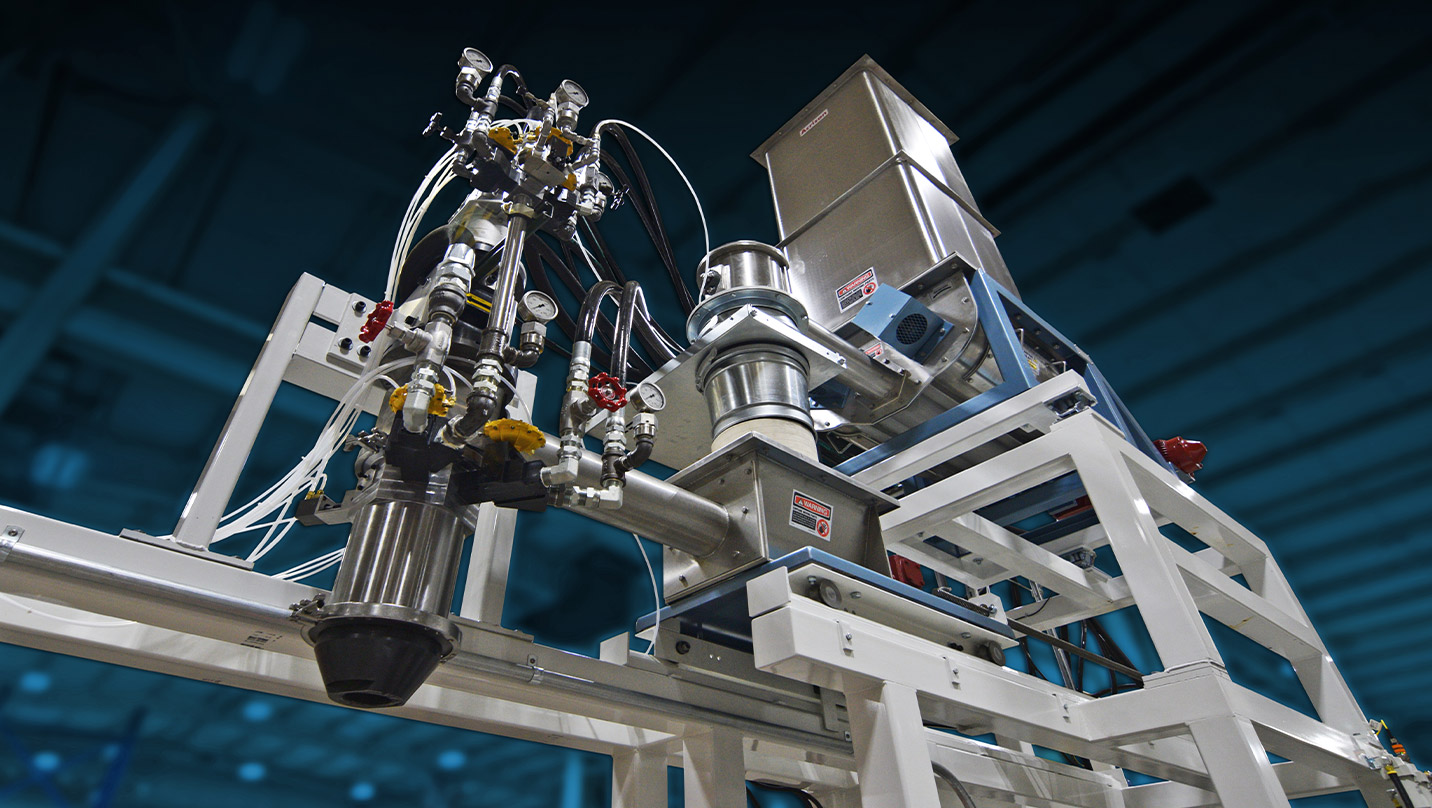

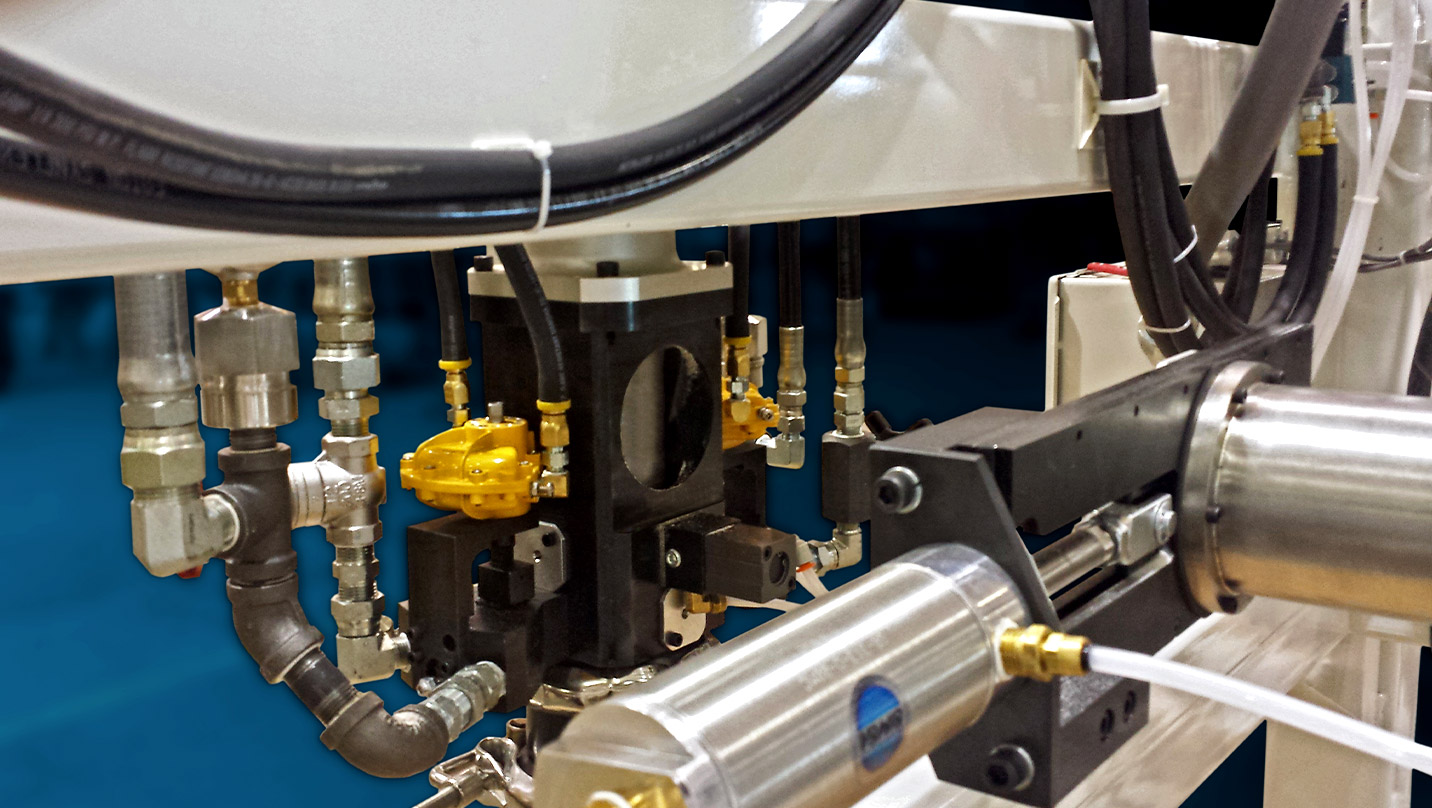

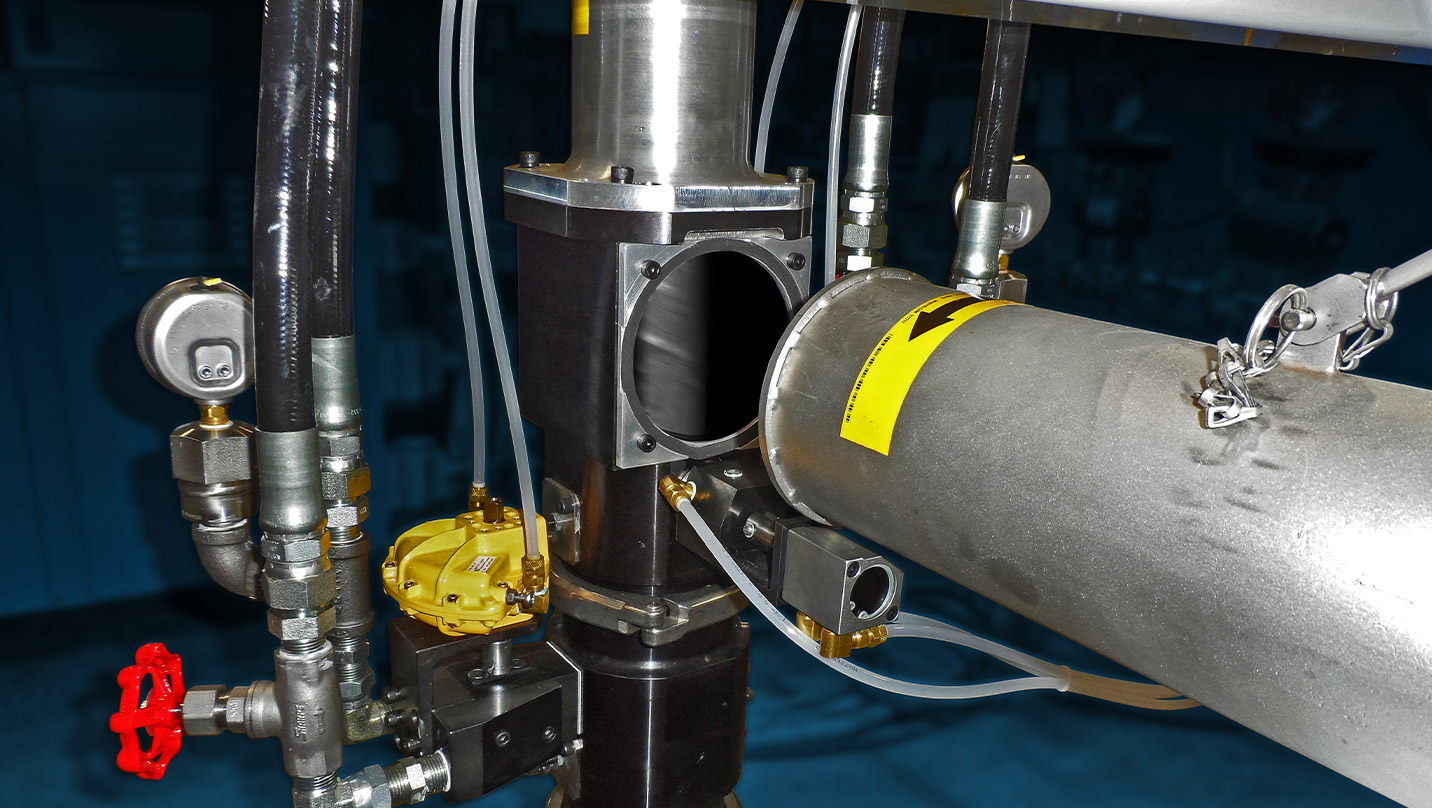

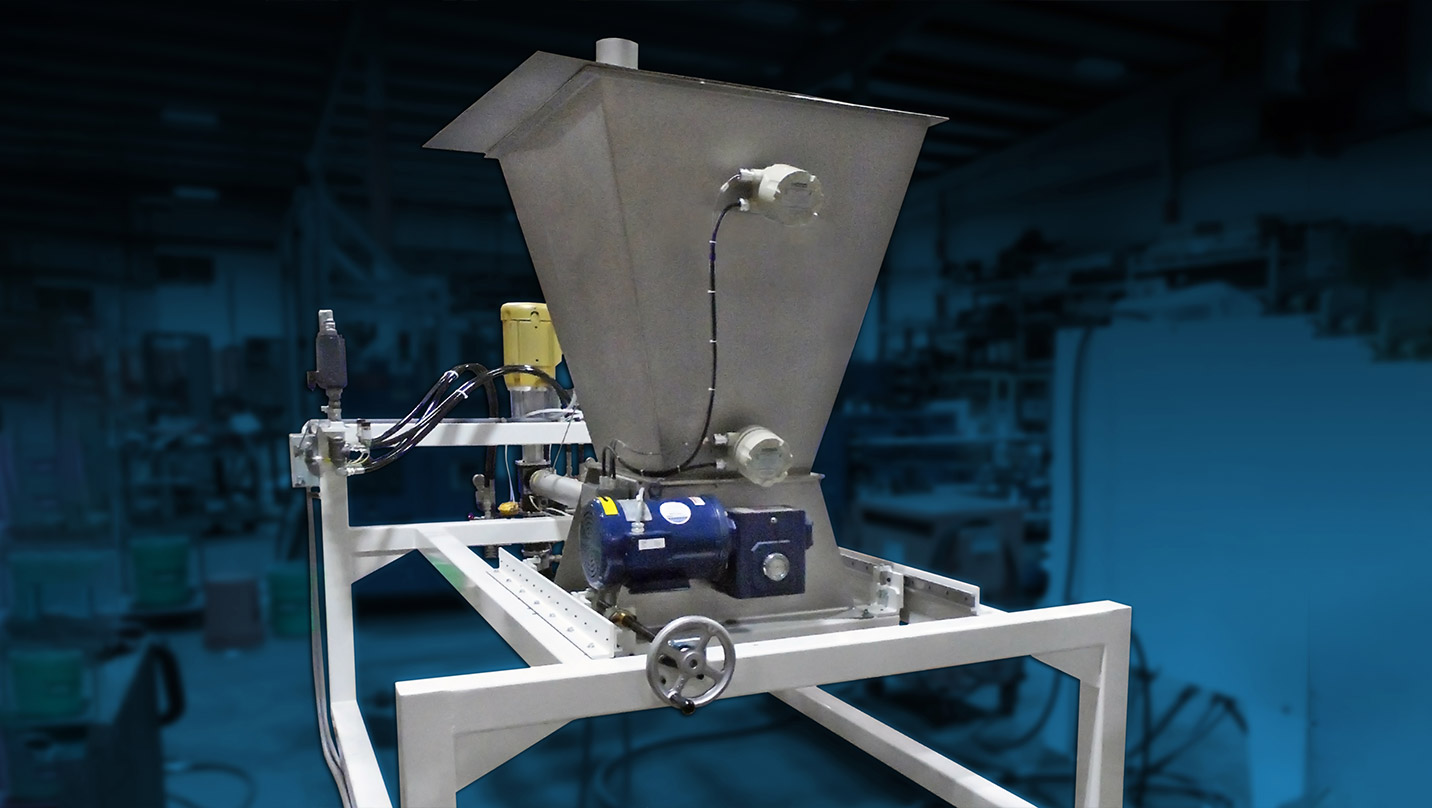

Edge-Sweets Company has patented mixing technology which is a unique improvement in the production of filled systems. The dry filler is accurately metered by a hopper feeder directly into the mix head, at which point the liquid streams are added.

Common Applications

Any application where incorporating a wide range of solid fillers directly into multi-component liquid systems is required.

Commonly Processed Materials

Polyurethanes, Epoxies, Polyesters

Commonly Processed Dry Fillers

We have processed the following fillers:

Download Brochure

Filled Systems Brochure [Downloadable PDF][Opens in New Window]

Descargar folleto

Sistemas Llenos Especificaciones [Descargable PDF][Se abre en ventana nueva]

Standard Features

Technical Specifications

Technical Specification Customization

Subscribe to our newsletter to keep up with the latest news + events