Please refresh page if loading fails

The ESCO 50-88 low-density flexible foam slitter is a low cost horizontal foam saw utilized for light duty foam processing for low to medium density polyurethane foams.

The 50-88 boasts touch-screen PLC controls and a variety of optional features to suit the user.

LEGACY MACHINE

Legacy machinery is not available for quotation.

Edge-Sweets is currently modernizing our legacy machines utilizing state-of-the-art manufacturing processes to offer high-quality, modern machines at a competitive price. Your sales engineer will have more information when legacy machines will be available for quotation again.

NOTICE

Starting in 2020 the 50-88 has been replaced by the HT Horizontal Slitter [Found Here].

Overview

The 50-88 PT flexible foam slitter is ESCO’s low cost horizontal foam saw utilized for light duty foam processing for low to medium density polyurethane foams.

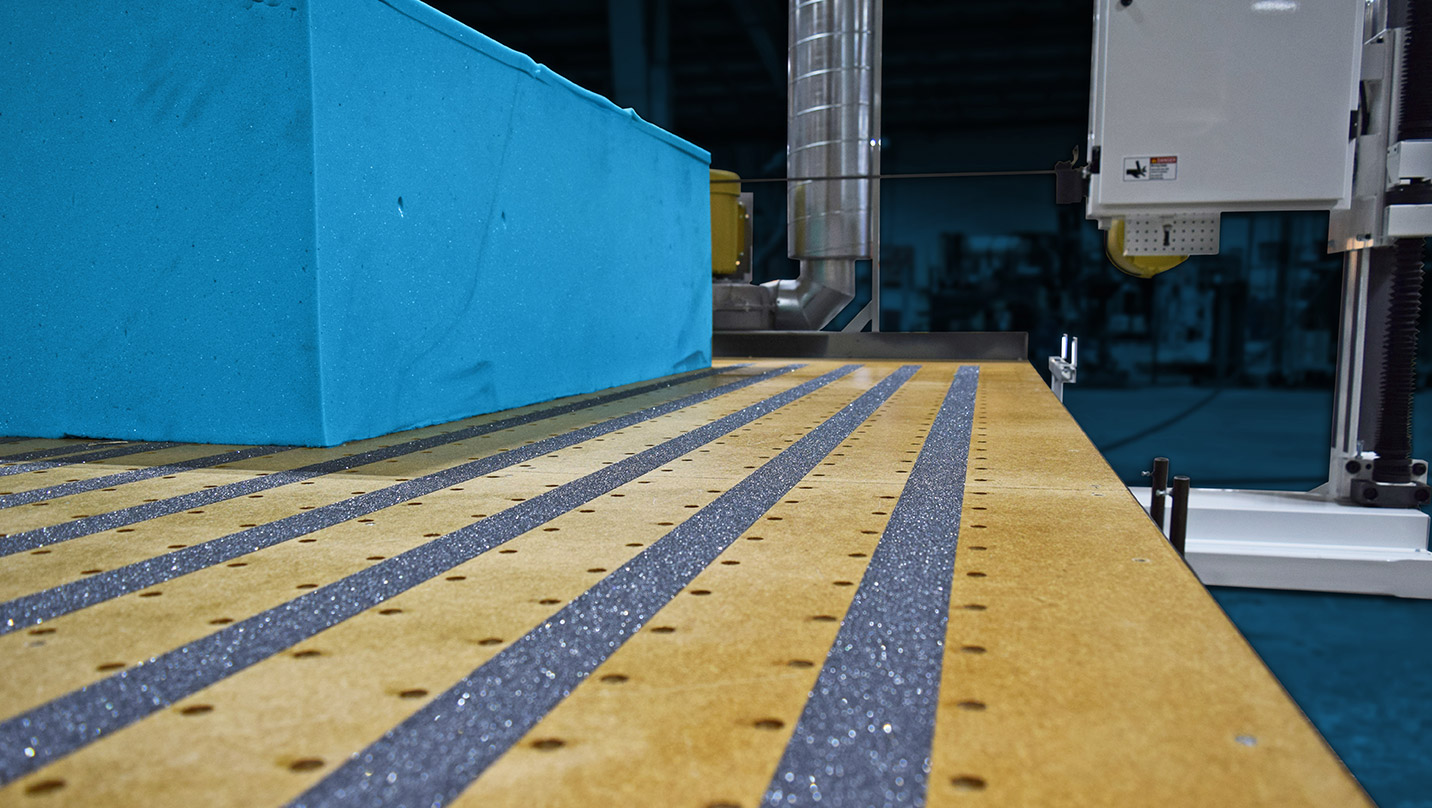

The machine offers a bonded blade guide with PLC controls and limited table options such as vacuum blowers, friction coatings and air lift options.

Common Applications

Furniture, Bedding, Packaging, Automotive, Medical

Commonly Processed Materials

PUR-ether and PUR-ester foam, PU rebond foam, reticulated foams, latex, Basotect®, Viscoelastic and similar low to medium-density foams

Download Brochure

50-88 Specifications [Downloadable PDF][Opens in New Window]

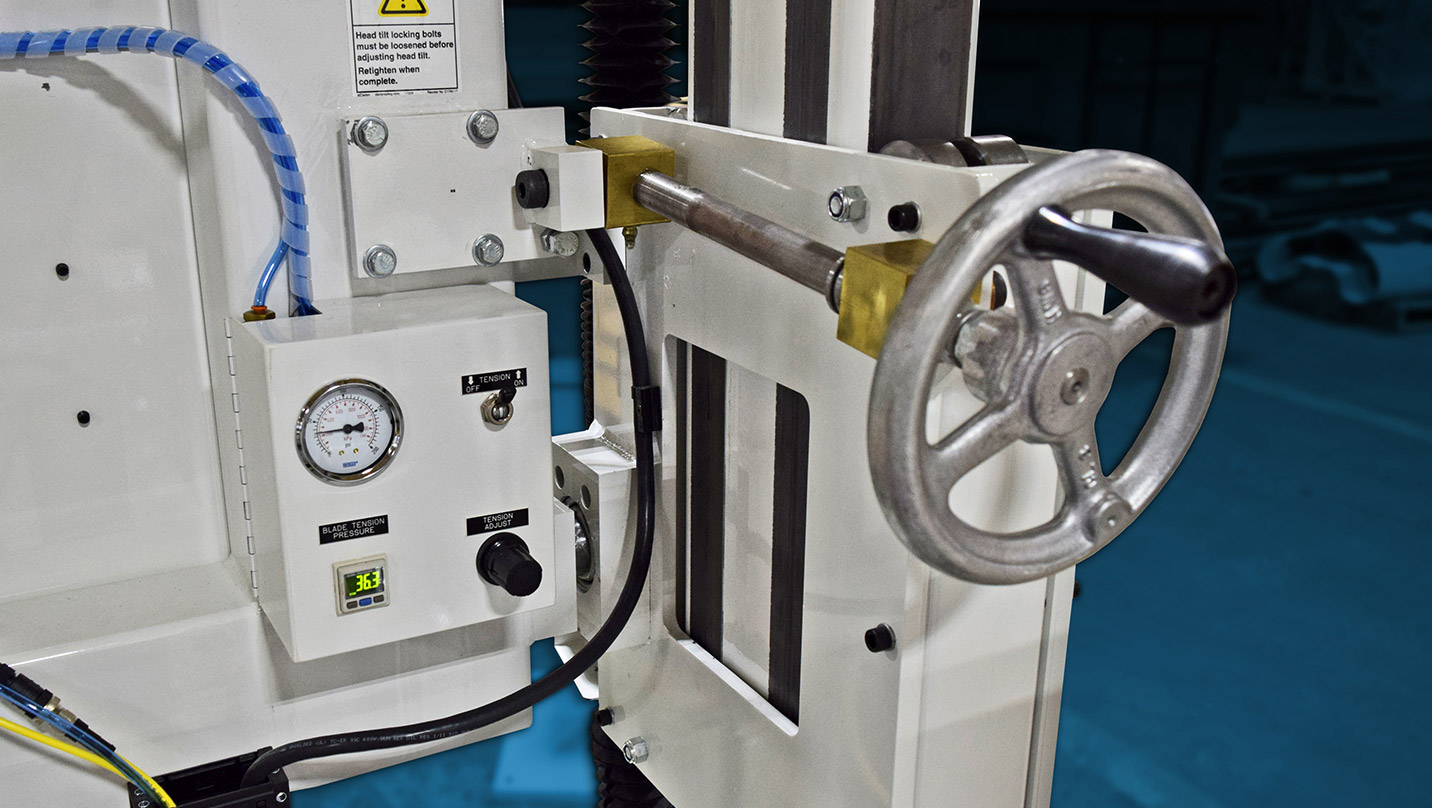

Operator Controls

Head Assembly

Table Assembly

Power Requirements

| Specifications | |||

|---|---|---|---|

| Models | 50-88 PT | 60-88 PT | 60-96 PT |

| Cutting Height | 50 IN [1270 MM] | 60 IN [1524 MM] | 60 IN [1524 MM] |

| Cutting Width | 88 IN [2235 MM] | 88 IN [2235 MM] | 96 IN [2438 MM] |

| Cutting Length | 132 IN [3350 MM] | ||

| Floor Space Required | |||

| Overall Width | 160 IN [4064 MM] | 160 IN [4064 MM] | 169 IN [4292 MM] |

| Overall Length | 324 IN [8230 MM] | ||

| Maximum Height | 152 IN [3860 MM] | 155 IN [3940 MM] | 163 IN [4140 MM] |

| Shipping Weight: 4500-6000 LBS [2040-2720 KG][Varies by Model/Options] | |||

Subscribe to our newsletter to keep up with the latest news + events