Please refresh page if loading fails

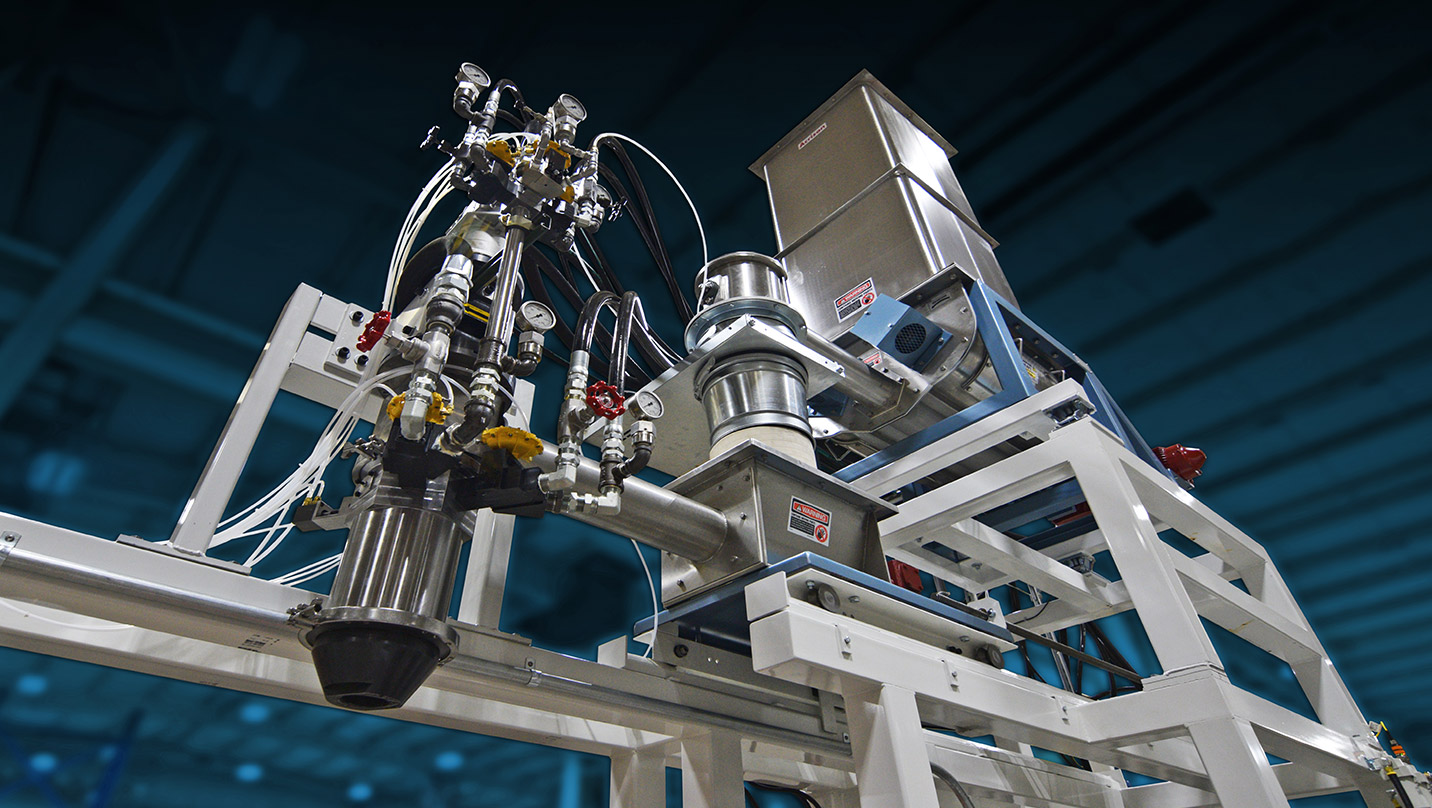

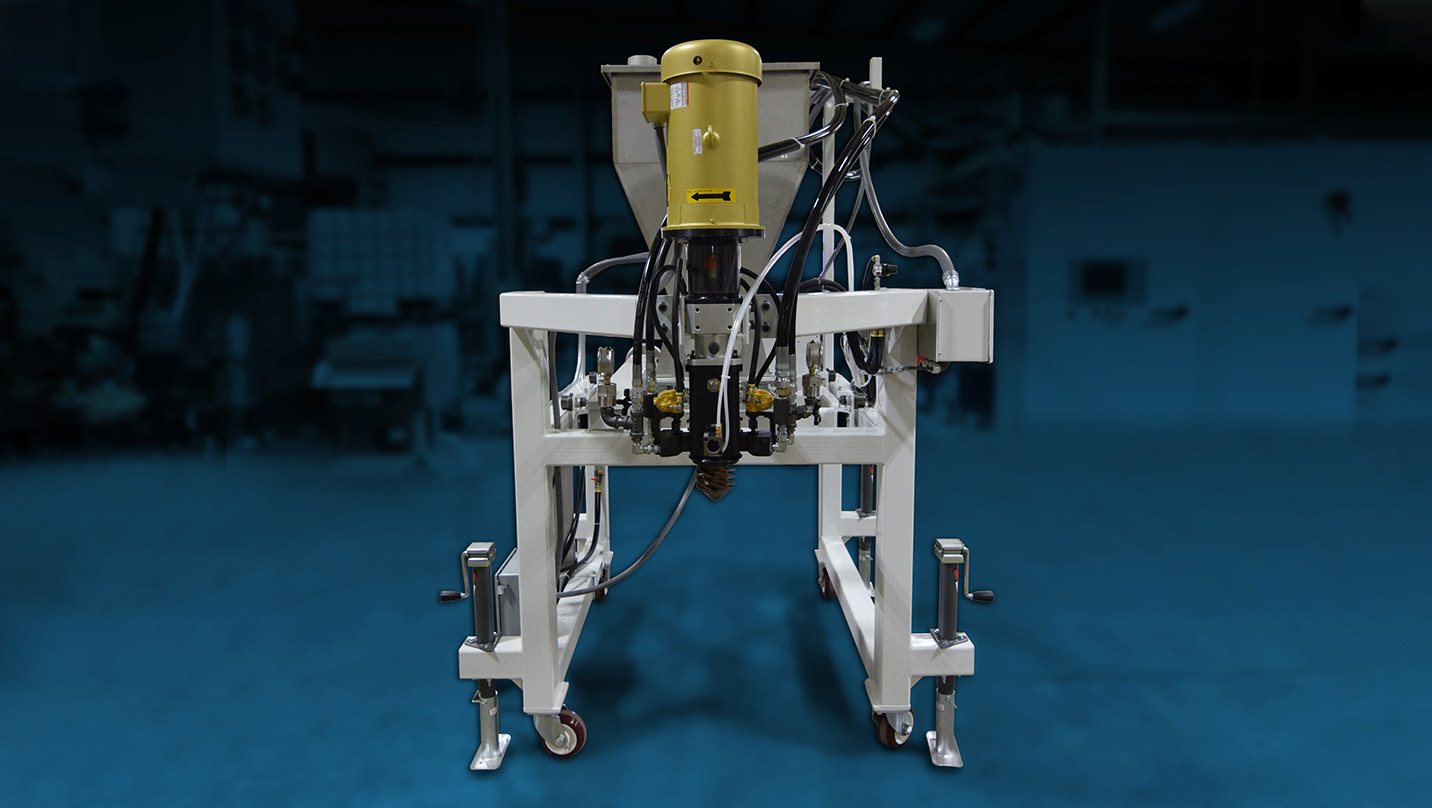

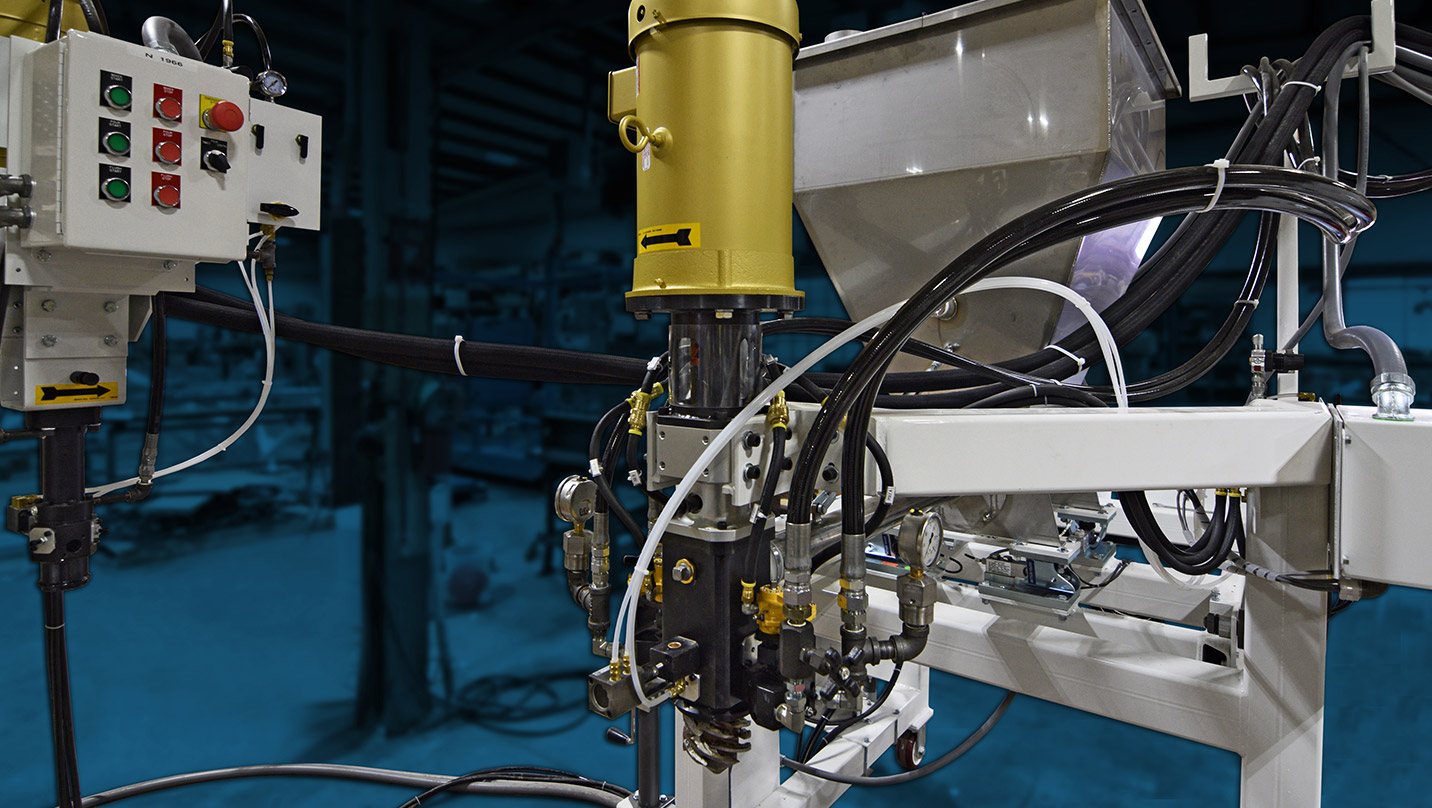

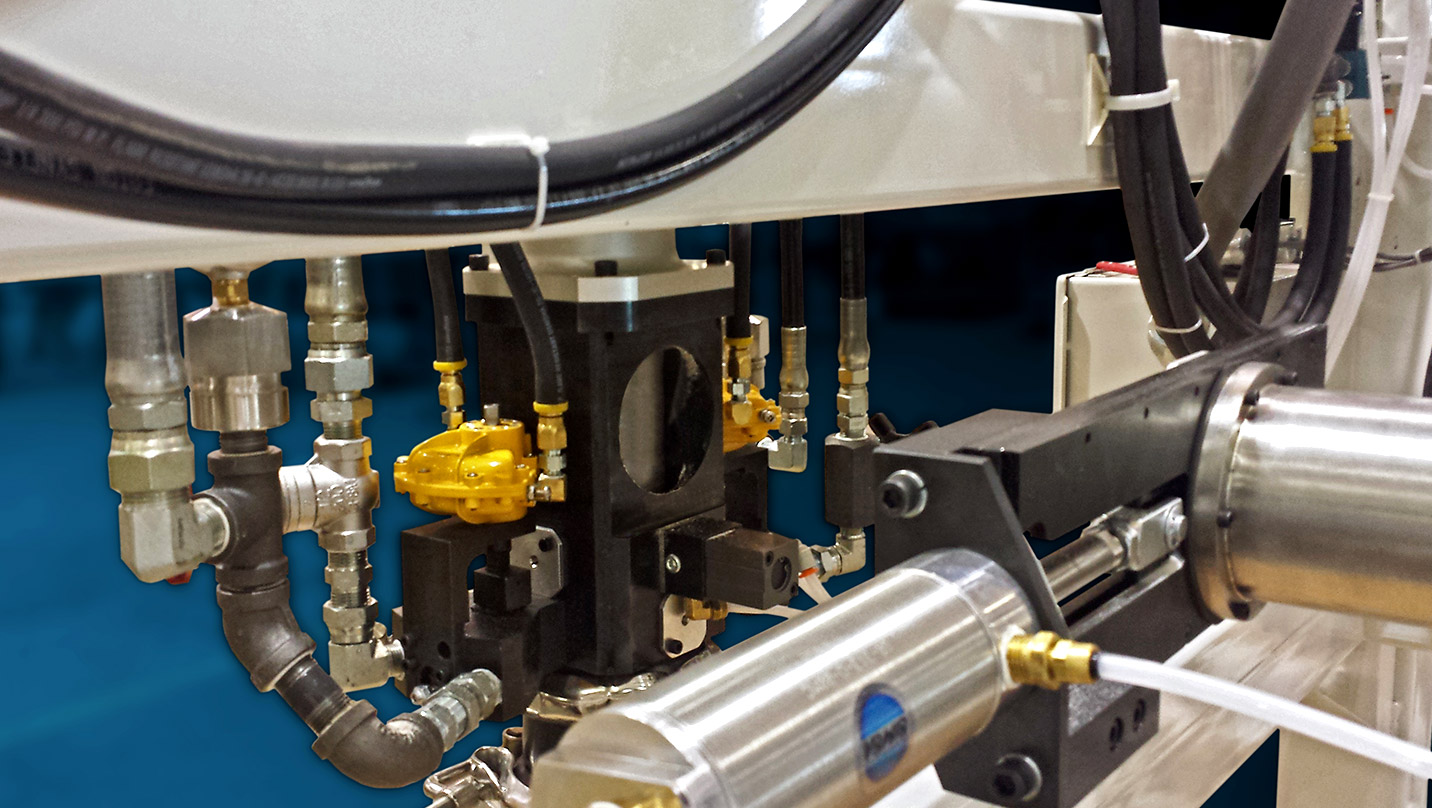

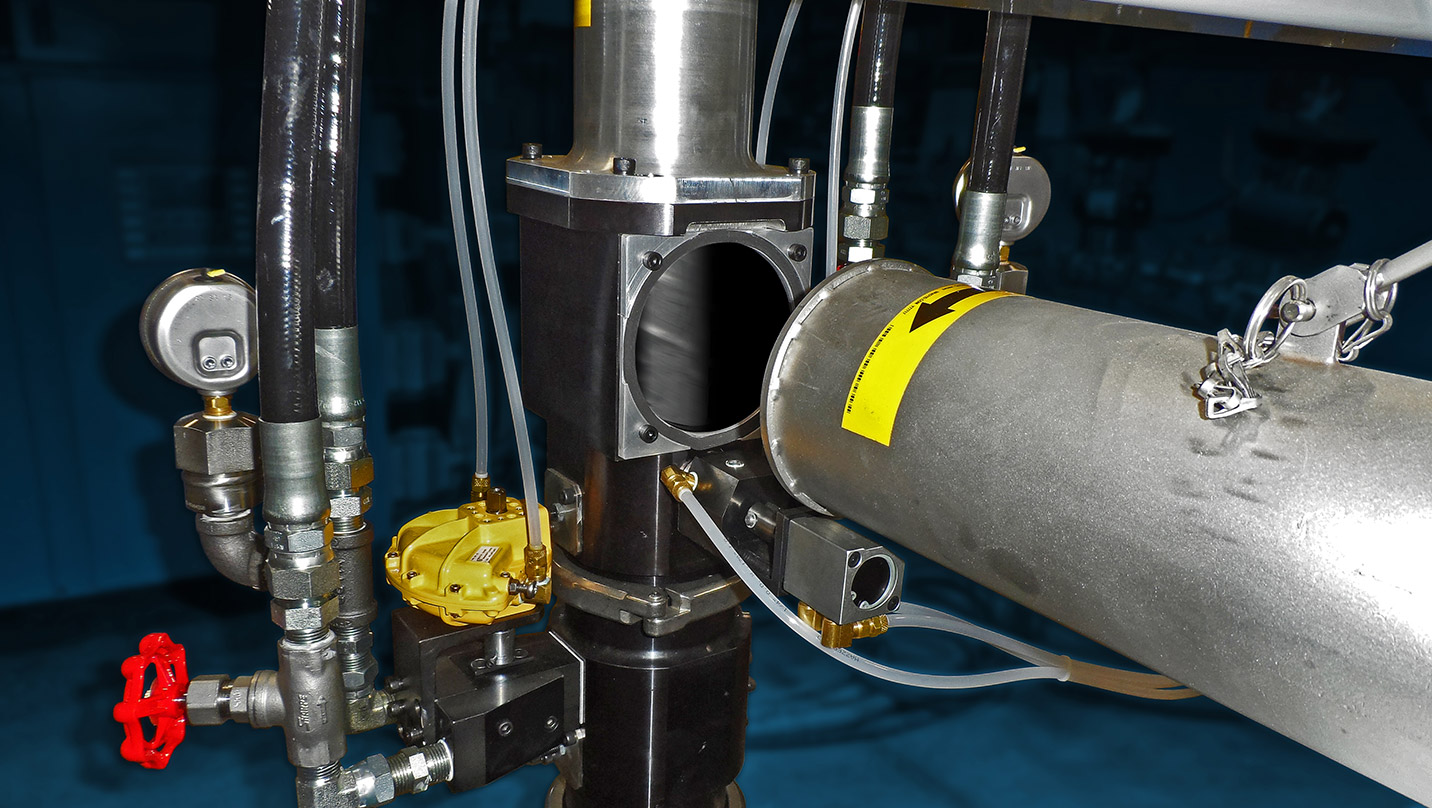

ESCO’s FFH system overcomes the challenges of costly bulk storage and pre-blending facilities along with the problems of settling, viscosity increases, separation and agglomeration which have all contributed to the limits of batch blend systems. Fillers are metered and mixed continuously without batching.

Overview

ESCO’s FFH system overcomes the challenges of costly bulk storage and pre-blending facilities along with the problems of settling, viscosity increases, separation and agglomeration which have all contributed to the limits of batch blend systems. Fillers are metered and mixed continuously without batching.

Blending

Advantages:

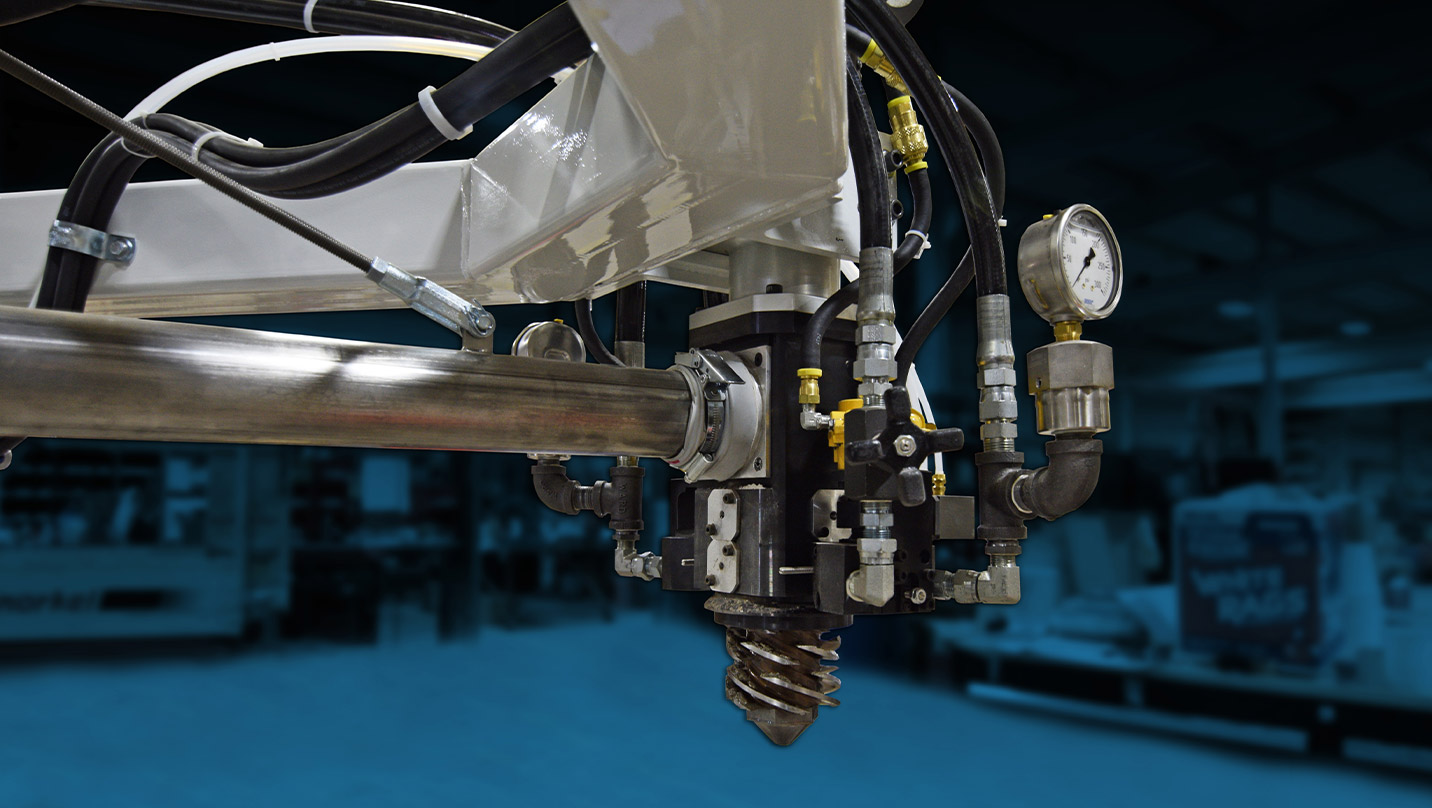

High volumes of dry filler can be added to the system. We have processed the following fillers:

Download Brochure

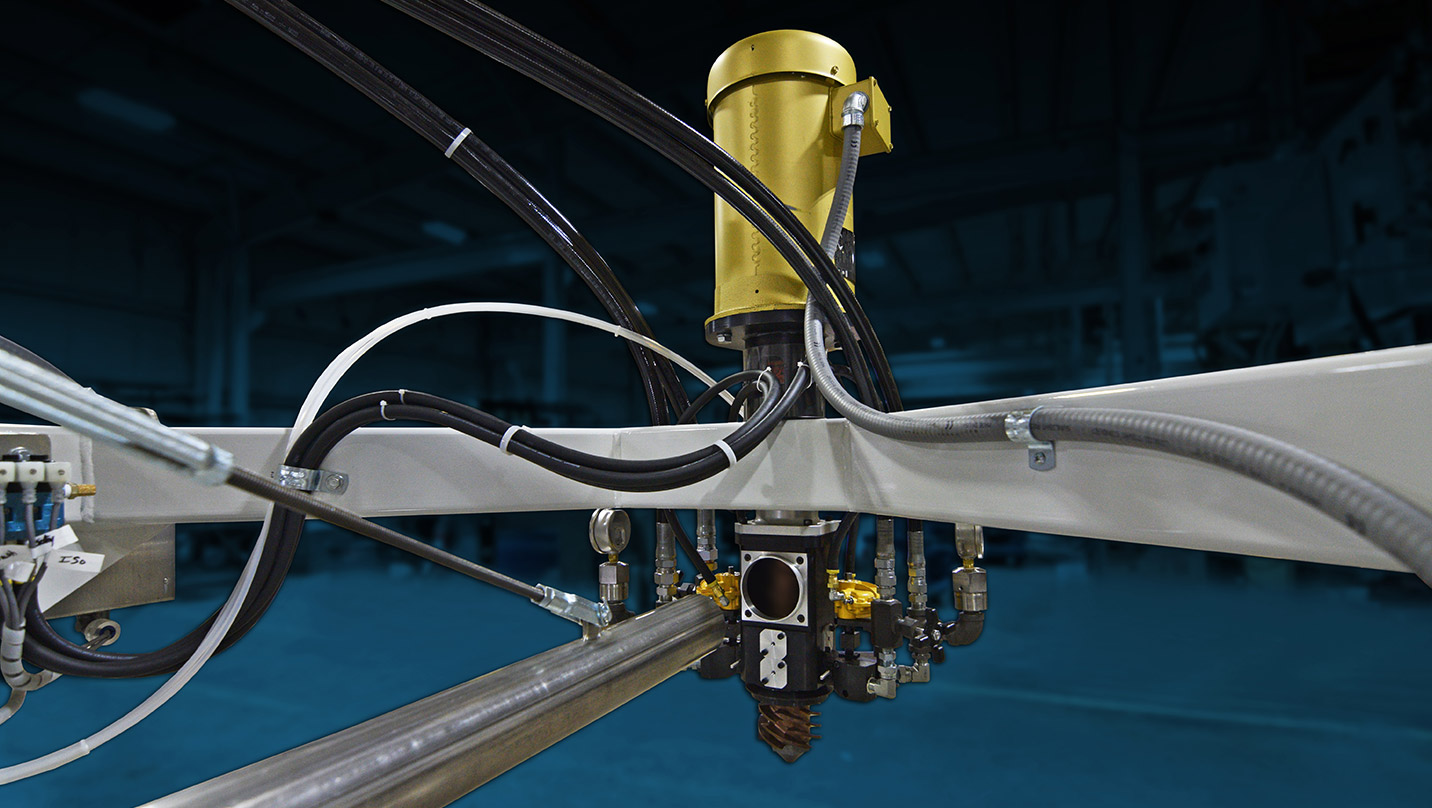

Mixhead Model Features

Nominal Output Rates:

Optional Features

Subscribe to our newsletter to keep up with the latest news + events